Testing 1,2,3… at MegaLab

By Stephen Law, Editor, EP&T

Electronics Test & Measurement Engineering accreditations certification Editor Pick Megalab testToronto-area one-stop shop serves multiple electronic test requirements

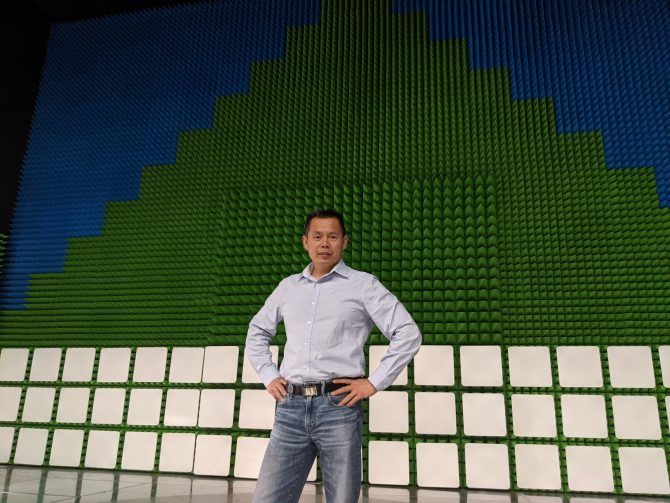

Just as Walmart or Costco serves its customers with every consumable need, Garry Lee has constructed a new facility outside of Toronto that can deliver any test requirement imaginable for an electronic design. Founder and partner of Megalab Group Inc., Lee recently opened his doors to a 45,000-square-foot building in Aurora, ON, specializing in independent laboratory testing services – including all-inclusive ISO 17025 A2LA accredited, EMC, product safety, mechanical & laboratory testing services.

“We provide testing and validation assistance services to help design teams assess their product’s performance – especially when that product needs to withstand rigorous environmental conditions,” says Lee, a 27-year veteran in electronic test services in Canada, who previously operated the firm as EMTS Labs Inc. in Stouffville ON.

Garry Lee, founder and partner of Megalab Group Inc., recently opened his doors to a 45,000-square-foot building in Aurora, ON, specializing in independent laboratory testing services. Source: Megalab Group

“The biggest difference we have here is the inclusion of more services. We’ve brought together the right people and the right equipment, and the right technology to provide that maximum client benefit,” says Sreyas Dasika, business manager at Megalab, which employs 13 people, nine of which are test engineering experts.

“In our previous location, we were having growing pains with respect to the space (at EMTS). Now we have unshackled that, and with our expanded footprint and services we can make the test experience much more enjoyable for the client,” Dasika notes.

“The name of our company (Megalab) speaks to our aspirations as to what we’re trying to do here. This building represents an all-inclusive test facility – we want to push our excellence and lessons that we’ve learned in test over several decades to all of our customers,” he adds.

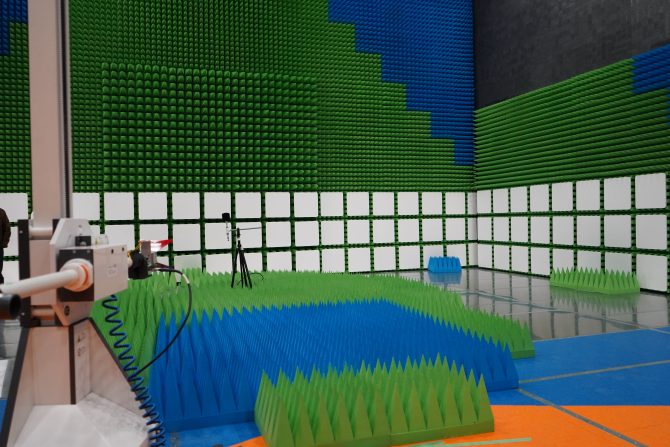

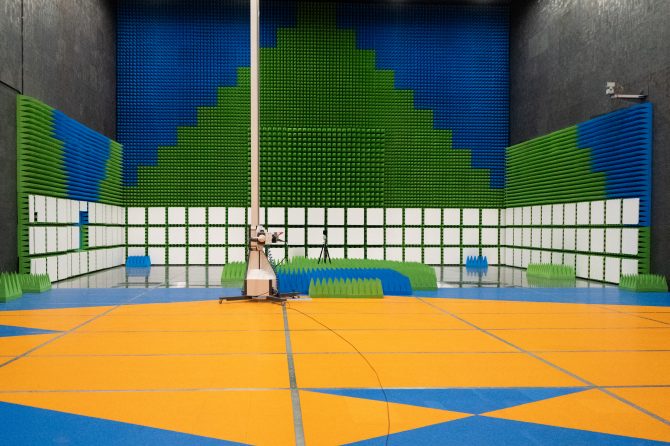

Megalabs’ facility can manage multiple key test requirements. Above, this measurement setup is for >1GHz with a dual ridge guide horn antenna. Source: Megalab Group

Design sectors served

Between the varied and unique industries it serves, the tests vary a lot, says Dasika. Each industry and even each component type has its own regulatory sub-standards that dictate how performance has to go for it.

“So, the implication for that is – in order for us to service each industry, we have to have the expertise and background to know the standards,” Dasika adds. “We are incredibly blessed, as we have years and years of experience working with everyone from automotive, military, medical, industrial, and consumer electronics manufacturers. Right across the board – these customers all have a commonality – and they need a fact validated.”

3M EMC radiated emissions test setup – Floor visible which serves a chamber ground plane, mounted on a 4mm remote control antenna mast. Source: Megalab Group

EMC/EMI testing

Dasika points out that essentially every circuit is susceptible to both magnetic waves on the outside, as well as being an emitter of these waves on the inside. As a result, every device needs to be assessed to make sure it cannot be interfered with and it does not interfere with other devices externally.

“The equipment used to test this means that all the signals must be measured in isolation. So, the reason why our test apparatus is so big and heavy is because it must literally block off the outside world,” he says.

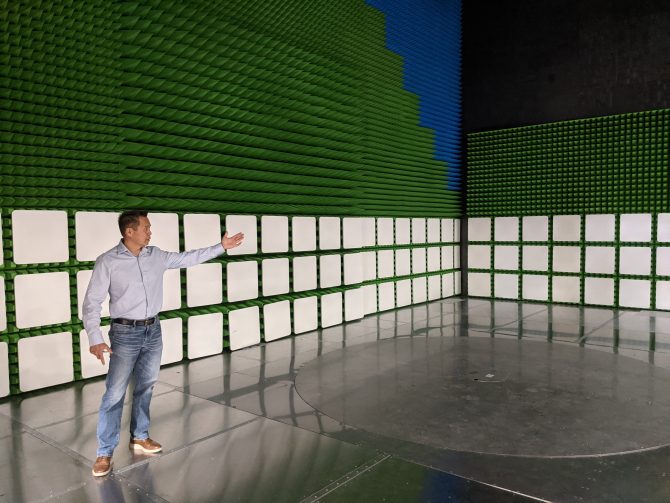

Among the testing services Megalab provides in this category includes: wireless, EMC pre-scan, EMI site survey, shielding efficacy, conducted emission, radiated emission, ESD and flicker & harmonic testing – to name most.

Product safety testing

These tests explore a variety of factors, such as detecting if a product gets too hot, will it shock the end-user, is the voltage correct on it. Megalab tests for some of the most very basic things that consumers take for granted in their devices.

“We are really trying to make sure that the regulatory hurdles that those products need to clear, can be assessed cleanly, impartially and that product users are safe,” says Dasika.

Among the safety testing services managed include: Construction review, CE mark, NRTL/C approvals, UKCA approvals, consumer & industrial safety, and medical design testing.

Environmental testing

When it comes to testing for environmental conditions, simulation scenarios are used to assess performance. As a sample example – if a product needs to operate in a hot environment for a long time and to continue operating.

“The entire nature of this type of testing directly relates to your product’s efficiency with waterproofness, corrosion, temperature resistance, ability to withstand shock and vibration resistance,” says Dasika. “These are all of the things that exist in nature and can beat your product down. These factors will destroy products that are not designed or tested to withstand them.”

Among some of the testing services Megalab provides includes: wireless, EMC pre-scan, EMI site survey, shielding efficacy, conducted emission, radiated emission, ESD and flicker & harmonic testing. Source: Megalab Group

Global market access

Every country has its own regulatory framework – thus, its own way to assess safety, according to Dasika. And, each country has similar, but divergent viewpoints. What this means is that each country has its own scheme and way it is to be done in order to make the product available in their particular market.

“We have experts on staff that are ex-engineers from some of the largest consulting organizations in the world – CSA, DEKRA, International Certification Agencies. They are able to assess the customer’s product – take their reports and tell you what the gap is to getting the product into any of these countries. The best part is, we have all of these services under the same roof,” Dasika says.

Turnkey test experience

Time to market is essential in any design process, as every OEM operates with two factors – time and money. Design engineers are all trying to make the time factor as short as possible and the cost factor as low as possible. If they cannot do those things, their businesses will fail – it’s as simple as that, Dasika notes.

“By recognizing these hurdles and challenges, our organization is structured to be that partner, who is going to push their goal as quickly as possible,” he adds.

Dasika underscores the importance of OEMs realizing the implications of freight, and its imposing associated costs. Shipping a prototype design from the OEM’s lab to a multitude of different labs for testing only extends the build process – thus lengthening the intended ‘time to market’, Dasika warns.

Megalab Group founder Garry Lee says his Toronto-area facility is capable of handling all-inclusive ISO 17025 A2LA accredited, EMC, product safety, mechanical & laboratory testing services.

Testing accreditations

Certified to the nth degree, Megalab’s engineering services are ISO/IEC 17025:2017 accredited, while also certified by ISTA as a transit packaging laboratory in the areas of processes and procedures, along with equipment qualification. The firm is also certified in the Controlled Goods Program to examine, possess or transfer controlled goods.

“We often find OEMs hitting design roadblocks when it comes to discerning regulatory or certification process hurdles. We want to be the OEMs all-inclusive answer to solving their problems on the engineering side,” he says.

When it comes to turnaround times on test needs, Megalab aims to get the job done as quickly as possible, according to Dasika. Simple or standard test procedures can be turned around quickly, such as in three to five business days. Some tests, however, can be limited by the fact that the test itself will take 35 days. As a result, Megalab moves to initiate the process as quickly as possible and return the results as speedy as possible.

“Our real focus is speed and efficiency – because once we achieve those qualities – our customer becomes speedy and efficient. We pass that time saving directly along to them, because we don’t want to bog them down with the process.