5 Valuable uses for stretchable electronic circuits

By Emily Newton, Editor-in-Chief, Revolutionized

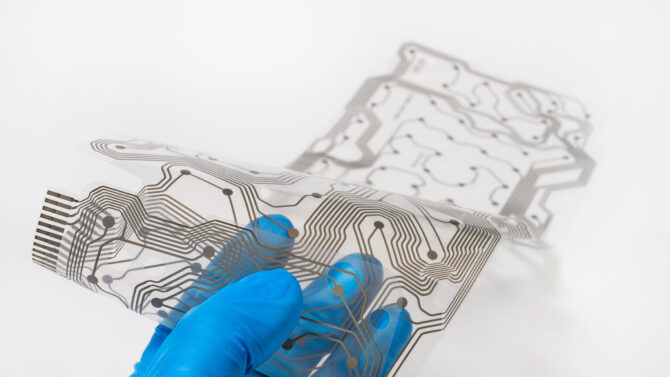

Electronics Engineering IoT Medical Printable Electronics Supply Chain Wearable Technology circuits electronic Flexible health IoT medical nanomaterials pcb pcbs piezoelectric Stretchability stretchable wearablesPrinted circuit boards (pcbs) have come a long way in a relatively short period. While rigid and rigid-flex pcbs are still the most common today, flexible circuits are growing in popularity. New materials and circuit printing technologies further this by enabling stretchable electronic circuits.

These newer options bend, compress and stretch without damaging their circuitry. This technology is opening a range of valuable new opportunities in electronics design as it becomes more accessible. Here are five of the most promising stretchable electronics applications to capitalize on in the next few years.

1. Wearables

Wearable devices are the most obvious application for stretchable electronics and one of the most promising. The wearable market is already a $61.3 billion industry according to Grand View Research, and stretchable circuits could make these products even more practical, boosting it further.

Current electronics’ reliance on rigid pcbs means wearables mostly take the form of smartwatches or other devices with small, inflexible components. Stretchable PCBs remove the need for these parts entirely, enabling connected clothing that doesn’t look or feel any different from normal outfits. Shirts, jackets, hats, socks, pants and more could all feature smart device functionality.

Consumer segments could capitalize on this potential to create fitness-tracking athletic apparel without the need for wristwear. Commercial markets could sell IoT-connected safety vests or work shirts to companies to improve workplace safety while ensuring employee comfort.

Source: Adobe Stock

2. Medical devices

Similarly, medical devices can use stretchable electronic circuits to expand telehealth services. Manufacturers could create health monitors that look and act like sensors or bandages. These technologies could provide real-time updates about a patient’s condition without requiring an in-person doctor’s appointment.

Bandages could use flexible sensors to track a wound’s healing, alerting user’s phones when they should change the dressing or reapply antibiotics. Other medical devices could use microneedles on a skin sticker to deliver medication without conventional shots or a bulky appliance.

Noninvasive, flexible IoT devices would boost emergency response times and improve the health care industry’s accessibility. The sector faces increasingly high demand and simultaneous staff shortages, making these advantages all-the-more critical. Stretchable medical devices would ensure these challenges don’t interfere with care quality.

3. Stress sensors

Stretchability can do more than just make some electronics more comfortable or convenient. Sensors could also monitor how circuits stretch and compress to gauge movement and stress. These flexible monitors are ideal for heavy industrial applications.

You could use a stretchable circuit to create a machine health sensor to stick on an industrial machine. The device would notice changes as the surface flexes over time. It could alert employees that the equipment is moving beyond acceptable parameters and needs maintenance.

This predictive repair approach can result in maintenance savings of 30%-40% and increased uptime. You could also market these sensors to building and construction firms, which could use them to monitor infrastructure health, such as watching for cracks in concrete or warping in wood.

4. Energy harvesting

Flexible circuits’ stretchability can also enable more effective energy harvesting systems. The piezoelectric effect causes some materials to generate an electric charge under mechanical stress. Stretchable electronic circuits can use this phenomenon to create their own power as they stretch and compress.

Energy gains from minor squishes and stretches would be minimal, but they’re enough to support a low-power IoT device. Wearables could use these circuits to power connected shoes as users walk in them. Industrial IoT sensors could use similar systems to generate electricity from movement in the equipment they monitor.

Energy harvesting from stretchable circuits would reduce the need for batteries, enabling smaller form factors and powering some devices with no carbon emissions. That sustainability will be important as there could be more than 29 billion IoT devices by 2030, according to information provided by Statista. On-device energy harvesting ensures that growth doesn’t result in a significant increase in fossil fuel consumption.

5. Product durability

Stretchable electronic circuits could also make electronics more durable. Even devices that don’t need to stretch can benefit from flexible PCBs because a bendable circuit holds up better to mechanical stress.

Stretchability also means compressibility, so a stretchable circuit can withstand harder impacts. The pcb would squish instead of breaking, preserving its sensitive components. Consequently, the devices these circuits power could keep functioning even when dropped.

This durability makes stretchable electronics an ideal choice for devices designed for outdoor activities, where they’d likely be subject to more stress. Similarly, manufacturing, construction and other heavy industries could use flexible circuits to power on-site electronics without worrying about breaking them.

Potential challenges of flexible circuits to consider

These stretchable electronics applications show considerable potential, but some obstacles remain. Manufacturing costs and complexity are some of the most significant.

Making stretchable circuits and components often means building them from nanomaterials, but items on this scale are far more expensive than their larger counterparts. A gram of gold nanoparticles costs roughly $80,000 to produce, whereas a gram of raw gold costs just $50. These prices will come down with time and technological advancement, but for now, they inhibit progress in flexible circuits.

These costs and complexity make it challenging to scale up the production of circuits relying on nanomaterials. Consequently, stretchable electronics remain best suited for high-end, niche purposes until nanotechnology becomes more accessible.

Some components are also harder to make stretchable than others. Power storage is a prime example. This inflexibility means many “stretchable” PCBs can only stretch to a certain point or in one or two directions, hindering their practicality. However, nanotech advancement and alternative power sources like energy harvesting help address the issue.

Stretchable electronic circuits are the future

Despite these challenges, the future of stretchable electronic circuits is bright. Engineers and manufacturers should keep these obstacles in mind, but with the right approach and more investment and advancement, this technology will become more accessible.

Stretchable electronics applications will take the IoT to new heights. It’s uncertain when technology will enable that shift, but the potential is too vast across too many use cases to ignore. It’s a question of when rather than if, and the time to be prepared is now.

————————

https://revolutionized.com/author/emily/

Emily Newton is an industrial journalist with over seven years of experience writing technical articles for the manufacturing, engineering and electronics sectors.