Microchip expands partnership with TSMC

EP&T Magazine

Electronics Semiconductors Supply Chain chip foundry microchip semiconductors TSMCSpecialized focus on 40nm processes remain part of a larger company initiative to increase supply chain resiliency

Microchip Technology has expanded its partnership with TSMC, the world’s leading semiconductor foundry, to enable a specialized 40nm manufacturing capacity at Japan Advanced Semiconductor Manufacturing Inc. (JASM), TSMC’s majority-owned manufacturing subsidiary in Kumamoto Prefecture, Japan. The partnership is part of Microchip’s ongoing strategy to build resiliency in its supply chain. Other initiatives include investing in additional technology to boost internal manufacturing capabilities and capacity, as well as establishing more geographical diversity and redundancy with wafer fab, foundry, assembly, test and OSAT partners.

“Microchip’s reputation for providing responsible and reliable supply management is enhanced with this new TSMC manufacturing path,” said Michael Finley, Microchip senior vice president of worldwide manufacturing and technology. “Customers can have confidence when designing our products into their applications and platforms, with the support of resilient and robust manufacturing capabilities.”

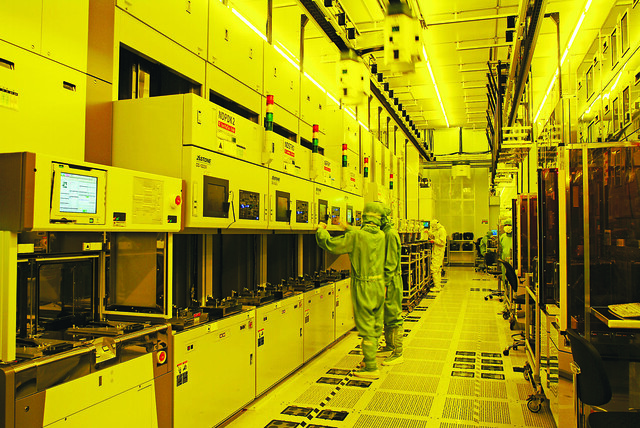

Microchip Technology has expanded its partnership with TSMC to enable a specialized 40nm manufacturing capacity at Japan Advanced Semiconductor Manufacturing Inc. Source: Microchip

The wafer capacity supply from JASM further strengthens Microchip’s ability to serve a broad base of global customers in a variety of markets including automotive, industrial and networking applications.

“This initiative with Microchip is further proof of TSMC’s commitment to supporting our customers’ long-term growth and innovation,” said Rose Castanares, senior vice president of business management at TSMC North America. “Our expanded collaboration with Microchip will ensure that as leading technologies continue to develop, so will our collective ability to manufacture and deliver those capabilities to global customers when they are needed.”

Advertisement

Microchip expands partnership with TSMC

EP&T Magazine

Electronics Semiconductors Supply Chain chips JASM Manufacturing microchip semiconductors TSMCSpecialized focus on 40nm processes remain part of a larger company initiative to increase supply chain resiliency

Microchip Technology has expanded its partnership with TSMC, the world’s leading semiconductor foundry, to enable a specialized 40nm manufacturing capacity at Japan Advanced Semiconductor Manufacturing Inc. (JASM), TSMC’s majority-owned manufacturing subsidiary in Kumamoto Prefecture, Japan. The partnership is part of Microchip’s ongoing strategy to build resiliency in its supply chain. Other initiatives include investing in additional technology to boost internal manufacturing capabilities and capacity, as well as establishing more geographical diversity and redundancy with wafer fab, foundry, assembly, test and OSAT partners.

“Microchip’s reputation for providing responsible and reliable supply management is enhanced with this new TSMC manufacturing path,” said Michael Finley, Microchip senior vice president of worldwide manufacturing and technology. “Customers can have confidence when designing our products into their applications and platforms, with the support of resilient and robust manufacturing capabilities.”

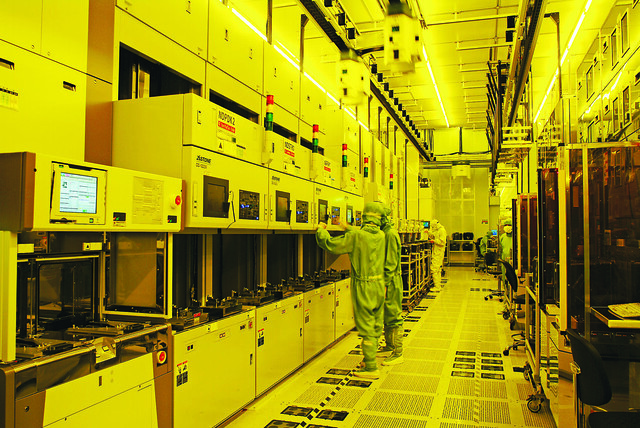

Microchip Technology

The wafer capacity supply from JASM further strengthens Microchip’s ability to serve a broad base of global customers in a variety of markets including automotive, industrial and networking applications.

“This initiative with Microchip is further proof of TSMC’s commitment to supporting our customers’ long-term growth and innovation,” said Rose Castanares, senior vice president of business management at TSMC North America. “Our expanded collaboration with Microchip will ensure that as leading technologies continue to develop, so will our collective ability to manufacture and deliver those capabilities to global customers when they are needed.”