Firms collaborate on microLED displays for AR glasses

EP&T Magazine

Automation / Robotics Electronics Optoelectronics Engineering Wearable Technology AR displays MicroLED optoelectronicsMICLEDI Microdisplays partners with GlobalFoundries to develop displays for use in augmented reality applications

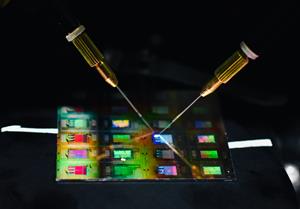

MICLEDI Microdisplays, a Belgium-based developer of microLED arrays for augmented reality (AR) glasses, is collaborating with GlobalFoundries (GF) to enable AR glasses to achieve the brightness, resolution, power, size, and economies of scale needed to become affordable for consumers.

Under the agreement, MICLEDI’s solution will be combined with GF’s 22FDX feature-rich platform that provides the leadership performance, ultra-low power and broad feature integration capability needed to build MICLEDI’s microLED arrays in mass production. Such companion integrated circuits (ICs), which can be customized for different customer applications, will provide the image processing, driver and control functions needed to complete the display modules using wafer-to-wafer hybrid bonding.

MICLEDI’s solution will be combined with GF’s 22FDX feature-rich platform that provides the leadership performance, ultra-low power and broad feature integration capability needed to build MICLEDI’s microLED arrays in mass production.

“Demand for AR and VR products will soar as users experience more immersive augmented reality,” said Ed Kaste, vice president of Industrial and Multi-Market at GlobalFoundries. “MICLEDI’s microLED solution, combined with GF’s 22FDX platform, addresses the demanding needs of future AR glasses by providing ultra-high resolution displays and advanced imaging technology that make stunning visual detail and color possible.”

“We are pleased to collaborate with GF as we move from pilot-line manufacturing to mass production in a world-class fab,” said Sean Lord, CEO at MICLEDI Microdisplays. “To enable optimum microdisplays for AR, MICLEDI has developed a unique and innovative solution for microLED manufacturing integrating both the controller IC and emitter module to leverage GF’s 300mm semiconductor manufacturing technology, capitalizing on manufacturing precision for product performance, high volume and low-cost.”