Earthquake halts silicon wafer facility in Japan

By Ken Kuo/Forrest Chen/Joanne Chiao, TrendForce

Electronics Semiconductors Supply Chain earthquake Japan semiconductors silicon TrendForce waferMLCC and semiconductor impact expected to be controllable, says TrendForce

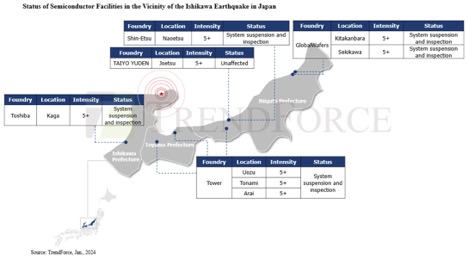

The impact of the recent earthquake in the northern region of Japan reveals that several key semiconductor-related facilities are located within the affected area, according to industry market research firm TrendForce. This includes MLCC manufacturer TAIYO YUDEN, silicon wafer (raw wafer) producers Shin-Etsu and GlobalWafers, and fabs such as Toshiba and TPSCo (a joint venture between Tower and Nuvoton).

Given the current downturn in the semiconductor industry and the off-peak season, along with existing component inventories and the fact that most factories are located in areas with seismic intensities of level 4 to 5—within the structural tolerance of these plants—preliminary inspections indicate no significant damage to the machinery, suggesting the impact is manageable.

In terms of silicon wafer production, Shin-Etsu and GlobalWafers’ facilities in Niigata are currently shut down for inspection. The crystal growth process in raw wafer manufacturing is particularly sensitive to seismic activity. However, most of Shin-Etsu’s crystal growth operations are primarily in the Fukushima area, thus experiencing limited impact from this earthquake. SUMCO reported no effects.

On the semiconductor front, Toshiba’s Kaga facility in the southwestern part of Ishikawa Prefecture is currently undergoing inspections. This site includes a six-inch and an eight-inch factory, along with a twelve-inch facility slated for completion in the 1H24. Additionally, the three TPSCo factories in Uozu, Tonami, and Arai—co-owned by Tower and Nuvoton (formerly Panasonic)—are all undergoing shutdowns for inspections. In contrast, USJC (UMC’s acquisition of the Mie Fujitsu plant area in 2019) was not affected.

MLCC manufacturer TAIYO YUDEN’s new Niigata plant, designed to withstand seismic activity up to level 7, reported no equipment damage. Murata (MLCC fabs only) and TDK’s MLCC plants experienced seismic intensities below level 4 and were not notably affected. However, Murata’s other factories (Non-Production MLCC) in Komatsu, Kanazawa, and Toyoma, which are in the areas with seismic intensity above 5, were closed for the New Year holiday, and staff are currently assessing any damage.