Brought to you by Phoenix Contact

Reliable connections for IIoT devices: Using simulation and measurement to optimize signal integrity

March 4, 2024

By Phoenix Contact

Shielded connectors help reduce or even eliminate interference. (Photo: Phoenix Contact)

Shielded connectors help reduce or even eliminate interference. (Photo: Phoenix Contact) The demands on connection technology performance are constantly increasing. With the steady increase in the networking of modern devices, the number of interfaces is also growing. The goal is to achieve data transmission that is impaired as little as possible. This depends on the interaction of all cables and connector components.

One property of board-to-board connectors that is directly related to signal integrity is impedance. The target impedance of a connector depends on the transmission technology of the connector application. Deviations from the target impedance reflect the data signal back to the transmitter. If the reflections become too high, the reflected and transmitted signals overlap. This results in impaired data transmission.

Connector impedance depends on several factors

Factors such as material selection, geometry, and the arrangement of the signal-routing components influence the impedance of a connector. An additional factor is the frequency, or the level transition time of the transmission technology used. This depends on the application, and the connector manufacturer cannot influence it. The trend is moving towards increasingly larger data volumes, and therefore, higher transmission frequencies with shorter level transition times.

Phoenix Contact is working to address these challenges. Regarding connector impedance, it is almost impossible to make generally valid statements about the best geometry, materials, or component arrangements since, in principle, the nominal impedances of the transmission technologies and the level transition times must also be considered.

Different optimization approaches for various connection components

No matter how consistent the effort is to provide all components with high signal integrity, the requirements of the components vary greatly. Data connectors of device interfaces such as compact SPE connectors, robust IP67 SPE connectors, or RJ45 connectors are usually standardized – the pin connector pattern and contact assignments are subject to cross-manufacturer standards.

These standards define specific requirements for signal integrity in the form of frequency-dependent limits for the transmission properties of the connectors, such as return loss or crosstalk. Phoenix Contact achieves a high level of signal integrity in these components through a careful selection of contact and insulation materials and designs not specified by the standards.

No standardized requirements for device-internal connections

Device-internal connections are usually not standardized. These connectors are interesting for customers with various transmission technologies. For example, in an Ethernet application, a board-to-board connector could be used in a device with an SPE interface. In this case, an impedance of 100 ohms would be ideal for the board-to-board connector. However, the same board-to-board connector could also encounter a USB protocol in another application where an impedance of 90 ohms would be advantageous. The same board-to-board connector could be used for both applications.

Since there are no generally valid wiring diagrams for this non-standard interface, signal integrity can be optimized explicitly by selecting a suitable contact assignment within the connector. For board-to-board connectors, simulations help to ensure the highest signal integrity for special applications. They often show customers unexpected areas of potential for their application.

Experience with individual optimization routines

The optimum is always the result of several iterations and the associated optimization routines. This applies to developing standardized or non-standardized connectors or configuring a specific application. The simulations often use parameters that are common in many applications.

When simulating board-to-board connectors, an impedance environment of 100 ohms for differential signals and 50 ohms for single-ended signals is usually applied. High signal integrity is present if the impedance behavior of the components deviates as little as possible from this target impedance. Simulations are prepared for such common parameter settings and common contact assignments.

Phoenix Contact can provide simulation results within a very short time. As part of design-in support, experts from Phoenix Contact run simulations based on individual parameters to provide product managers and engineers with the best possible advice on selecting optimum connector combinations and suitable contact assignments. The appropriate impedances and level transition times can be considered, as can interference in the form of crosstalk from other signals in the same connector or interference from other components on the PCB. When interference comes from other components, observation or simulation of the electric and magnetic fields is a suitable approach. Shielded connectors help to reduce or even eliminate this interference entirely.

Individual support for optimally appropriate solutions and products

Based on the values that customers provide, Phoenix Contact starts a customer-specific simulation and uses it to derive suggestions for suitable combinations of items and contact assignments. The team informs customers about findings, answers questions, and then provides the appropriate documentation.

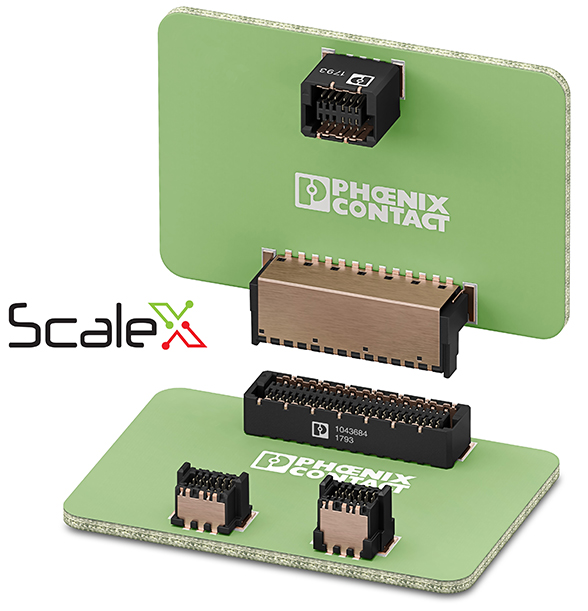

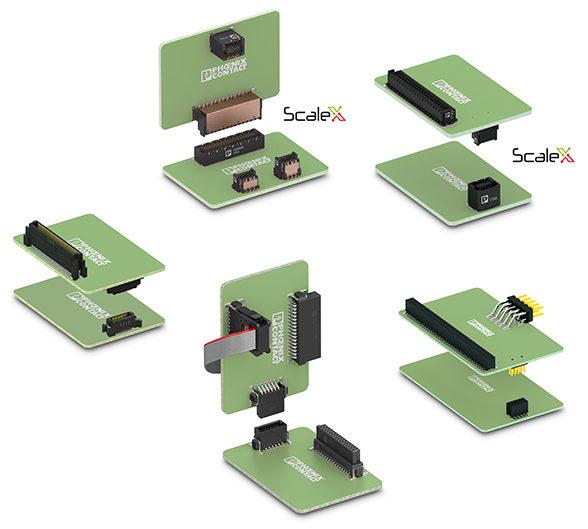

These individual simulations can usually be completed within a few days. To do so, the engineers need information on the specific application, such as the arrangement of the printed circuit boards in the device, the type of data transmission, or the target impedance of the system. Phoenix Contact’s board-to-board connectors offer a high degree of flexibility, particularly in terms of PCB arrangements. Mezzanine, coplanar, and backplane arrangements with different PCB spacing are all possible, as are connections with preassembled flat-ribbon cables.

Phoenix Contact’s board-to-board connectors offer a high degree of flexibility. (Photo: Phoenix Contact)

Direct communication between the simulation team at Phoenix Contact and design engineers is essential. This has repeatedly led to unexpected optimization potential for signal integrity in past projects, such as through an alternative contact assignment or the use of shielded connectors. Phoenix Contact provides support for device development, as local contact persons establish contact with the relevant specialists within the company.

Conclusion

Today’s market offers a variety of connectors for many different applications with multiple versions and price levels. In most of these applications, the quality and security of data transmission are important aspects. Phoenix Contact offers a broad portfolio of data connectors with the highest possible signal integrity and comprehensive design-in support. Engineers can look back on a wealth of experience in simulations and tests. The simulation software used is optimally adapted to the products we produce. The experts have already supported countless customers with suitable connectors for individual applications with optimum data transmission.

Design-in support can help determine the best connector combination and contact assignment. (Photo: Phoenix Contact)

For more information, please visit www.phoenixcontact.com