Understanding Schematics: The Not-So-Simple Foundation of a PCB Design Project

By EMA Design Automation, Inc.

Electronics Engineering Software Engineering Design pcb Schematics Schematics software softwareUnderstanding key schematic design fundamentals is of utmost importance when beginning a PCB design project. This foundation of knowledge begins with what a schematic is and its main purpose.

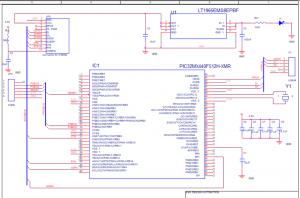

Creating a schematic diagram is a way for an engineer to quickly document the elements of a complex circuit in a way which can be easily read and understood. It allows the engineer to quickly document the elements of a complex circuit in a way that is easy-to-read and understand. A properly captured schematic helps the PCB design process by hierarchically organizing the electrical areas of the evolving PCB design.

A complex schematic drawing package, or design database, usually starts with a system-block diagram showing all the parts of the design on the first sheet. A completed schematic should look simple and basic to any viewing stakeholder, such as a field service tech or test engineer. However, stakeholders such as those involved in design and layout leverage the vast amounts of data embedded within the ECAD schematic to complete the design layout.

Standardization

Throughout the years, engineers have been using some creative methods to capture schematics. Capture software has very few input requirements and can be used by anyone to make connections between almost anything. For instance, ECAD tools today are so easy to use even a surfer with no electrical knowledge could create a schematic symbol for a beach hut, a surf shop, a surfboard, and a wave and tie them together with connections to show other surfers what he would be doing throughout the day:

Examining this simple schematic, it is easy to see the surfer is going to leave his hut, go to the surf shop, come out with a surfboard, and head for the ocean to surf a wave. Now, ask three different EE’s to draw a schematic depicting a surfer’s day. As you can imagine, each EE will have his or her own take on what the beach hut looks like: does it have a back door or a basement; is it solar powered or off grid? How an EE would depict a surf shop or surfboard schematic symbol is anyone’s guess. When it comes to depicting a wave, well, let’s just say EE’s can be very knowledgeable about waves observed on an oscilloscope, but schematically-depicting a wave viewed from a beach will again yield a wide variety of interpretations, leading to confusion amongst those trying to decipher these simple schematic drawings.

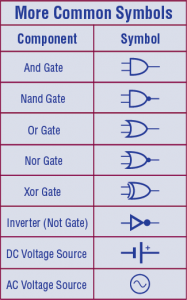

The electronics industry foresaw this issue many years ago and as a result, organizations formed to standardize the way schematic symbols are depicted. ASME Y14.44-2008 and IEEE 315-1975 define how to reference and annotate components of electronic devices. Below is a quick list of reference designators and their matching symbols. A complete list is on the IEEE standard’s website.

Successful schematic capture is basically the process of creating simple schematic symbols which contain simple nodal contacts. These symbols represent simple part configurations which are each documented on a page of the manufacturer’s data sheet.

It is important to recognize the goal of capturing the schematic—to define or “capture” as much data as required to be imported into the layout database, so it can be leveraged to create the physical aspects of the design. As previously mentioned, the schematic is a simplified, symbolic representation of what will materialize as a physical PCB assembly.

Default Values and Software Automation

There are many undesirable outcomes which can stem from naively using defaulted values and blindly launching software automation without understanding. If you were to replicate a simple schematic symbol hundreds of times in a schematic which contains incomplete or misunderstood data, the results would be catastrophic.

So ECAD suppliers have made schematic capture easier, right? Well yes, but it’s not inherently simple. Over the years, to help address complex design issues the ECAD industry has unintentionally made schematic capture rather complicated by adding vast amounts of complex functionality. It is now the responsibility of the EE to investigate these complexities, and understand them thoroughly, before implementing them. As mentioned, a basic ECAD schematic library symbol represents the connectivity of an electronic part within a circuit on the schematic. However, the explosion of ECAD tool functionality has required electronics designers to take on a much more holistic view of the selected part. Information beyond pin assignment and connectivity can now be embedded into the part symbol. Functionality can be added to the modern schematic symbol to access multiple PCB layout footprints which contain 3D representations of the part—a recent boon to the “mechatronics” movement which is quickly emerging.

As we can see, the simple building blocks of a schematic diagram are no longer simple due to advanced requirements for functionality. They remain the building blocks, so it is more important than ever to confirm every attribute entered is accurate.

Schematic Layout Best Practices

When creating schematic symbols, simplicity is key. There are not many rules regarding the creation of a symbol in a schematic unless they are pre-defined in an internal company design specification. For EE’s working on a design team, it is essential for a symbol to have some form of consistency.

Symbol creators are free to replicate the part connectivity information in the symbol almost any way they see fit, but for those without pre-existing company standards, there are a couple of basic guidelines which will help with consistency:

- For bi-directional discrete parts, consistently orient the symbol within the editor either horizontally, with pin one to the left, or vertically with pin one at the top.

- For uni-directional part symbols, follow the same guidelines as mentioned for bi-directional, but carefully consider information which may need to be added to the symbol to prevent the part from being installed backwards.

Communicating Design Intent and Design Tips

Effective communication of design intent is an essential part of the schematic design process. Since it will be used by various stakeholders through the design cycle (review, layout, testing, etc.) schematics need to be easy-to-read and understand. As mentioned previously, schematic readability is subjective, so keep the end user in mind and organize it in a way that is anticipated by the reader.

Questions to ask yourself before you begin designing:

- Are special notes or performances requirements expected?

- Do current-carrying capacity or impedance need to be noted?

- Will the schematic be viewed electronically or on paper?

To create an effective schematic layout, there are some tried and true tips that need to be followed, the most basic being: Include as much information as possible. This includes part values, manufacturing information and net names. Have a good library of parts containing all the necessary symbols, footprints and part attributes. This will reduce errors in throughout designs and save time.

The second step is to determine if the design with be flat or hierarchical. This will also help with the flow of the schematic. A flat design is a single or multi-sheet design with all pages at the same level. A hierarchical design includes one or more modules which can be opened to view the corresponding schematic. These can be used for complex, multi-sheet designs where the circuit is broken down into building blocks and are typical when reusing parts of circuitry, like a power module.

Schematics: Anything but Simple

While a completed schematic should look basic to any viewing stakeholder, the information included within them is anything but simple. Stakeholders, such as those involved in design and layout, leverage the vast amounts of data embedded within the ECAD schematic to complete the design layout and influence decisions along the way.

Schematic diagrams can range from straightforward to complex based on the design being captured. However, the methodology used to capture the schematic can be kept simple by following industry standards, implementing consistency, common sense, and knowing what to watch out for.