Production considerations for electronic design start-ups

By Marjory Craw-Ivanco, V.P. operations, Urtech Manufacturing

Electronics Production / Materials Contract Manufacturing Engineering Supply ChainUnderstanding the pitfalls and demands of bringing new hardware to market

The idea

There is nothing more exciting than having that ‘Eureka’ moment, when you have an outstanding idea that you are convinced it will become the next revolutionary trend breaking, phenomenal device. You talk to friends and colleagues who are blown away by your ability to innovate. However, before you run out and remortgage your (or your parents) house, please consider the following key pieces of advice and potential guidance from someone who has navigated the world of hardware design, new product launch and product sustainability and evolution.

The level headed review

Almost by definition, one must consider a start-up as an organization dedicated to creating something new under conditions of extreme uncertainty. Before you venture into the arena please consider the following:

* Know your why: Not only is it important to understand the functionality of your product and the value it will bring to your customers but there is an innate requirement that, to embark on the rigorous journey of bringing a product to market, one needs to really understand why this product will be differentiated in the Market, why is your product so special?

* Pick your co-founders: It can become really tense during product design and launch. Make sure you know who you will be working with and their tolerance for risk.

* Identify your minimal viable product: Hopefully your idea will be the first in a long series of innovations, but, don’t lose your shirt until you have identified that there is a market for your product.

* Price your product (know your margin): Create your brand. Brand definition and recognition can be really key differentiators. I, like most technical engineering types, never paid much attention to what the packaging looked like, as I was always more interested in functionality. Don’t be fooled by function, in order to get people to try or test your device you must first get them to buy it, so branding is key.

* Know your funding sources: There is a big difference between getting a loan from friends and Family, a Crowdfunding source and the bank. Understand the scope of the financing available, the expected returns and the time frame till profitability is required. Funding mechanisms can very quickly influence your flexibility and schedule.

* Think about building your sales channels: It’s all very well to have product, but getting out there at the right time and in the right locations will be critical to your success.

* Know your time to market: Factor in everything not just the design time.

Proof of concept

Once you have considered all of these factors then you might be ready to move forward to your proof of concept. The proof of concept (first prototype) could be constructed on a bench in a lab or the garage, but once you have determined that the concept works and you have made whatever iterations you deem necessary, you may then transition to a functional prototype.

The functional prototype

The functional or working prototype generally has the form, fit and function of your final product. This may be developed with rudimentary electronics and 3D printed plastics and casings, but it should be good enough to help support your funding campaigns. Once you are happy with the functional prototype it is time to think about how you will build in volume. A key consideration is ‘design for manufacturing’.

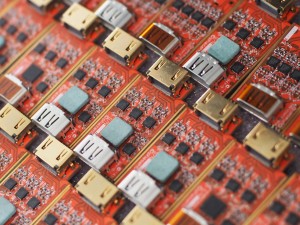

Design for manufacturing

When you employ DFM tools then details such as: component selection, processing parameters, functional test systems and ease of assembly can be modified to ensure the highest possible yield and the lowest possible cost.

At this stage, you may also wish to consider some form of reliability testing, either drop tests, temperature and humidity cycling or shipping tests to ensure that once released to the market the product can be shipped and distributed safely.

Supply chain

Make sure you select good parts. Part selection is critical for a number of reasons ranging from functionality to continuity of supply and delivery. This may be of particular importance if you identify a custom part, be sure whoever is involved in the delivery of the custom part has scalability. It may also be wise to engage your factory partner on alternate component selections and alternate vendor lists to mitigate risks (and costs) associated with supply.

Certification

Often times in order to sell, or give away, a few units you may not need any type of product certification. However, before you start building your product in volume you will need to seek approval at a certified lab, to demonstrate that your product conforms to FCC, or CSA or UL. Depending on the product functionality. This is likely also a good time to research product assurances.

Manufacturing

The next step is to choose your factory partner. This is a very critical step in your launch process. Although a great deal of manufacturing has transitioned to Asia or Mexico over the past decade – driven by what is considered to be lower cost manufacturing facilities – a new company should carefully consider the actual landed cost of pursuing this option. Typically, in order to be fully successful with a product launch oversees, companies have to install several engineers in the facility for extended periods of time to ensure build and design protocols are adhered to. Of course, it is possible to work with one of the very large contract manufacturers, however, being a small fish in a big pond can have its drawbacks for relatively small start-up companies. Before heading overseas, it may make sense to check-out some local facilities to begin the production process. It will be easier to communicate and control the process, monitor quality and make any necessary last minute changes. Indeed, we at Urtech Manufacturing, have several North American customers who have decided to ‘re-shore’ its off-shore activities at our factory in Burlington Ontario due to quality, price, proximity, delivery and the convenience of working right here at home.

Software/firmware and product testing

Firmware changes frequently, particularly in new product design. Consider how and where you want to program any devices, either pre-build or post build. Also product testing is critical to ensure product quality prior to shipping. Often times during product development new companies do not have the resource bandwidth to develop product test. This is where a good factory partner can assist you in ensuring the test coverage is suitable and adequate for your circumstances.

Packing, shipping and fulfilment

Of course, there are several ways this can be done. Bulk shipments from the factory to your facility may be the process that you would like to use if you would like to own the final touch on the product before it reaches the end customer. For individual consumer commercial distribution it may be necessary to have specially designed point of sale boxes that are packed with various accessories and the necessary cosmetic guidelines that reflect the brand of your product. These boxes would then be introduced to a master carton for shipping. Prior to shipping, all of the packaging material should be tested to ensure that the packages maintain integrity during the shipping process.

Reverse logistics

One very important consideration that should not be forgotten, is that sometimes devices fail in the field. When they do, they need to be replaced and repaired or recycled. Understanding and assessing the field fail rate is a very important factor in establishing the overall technical and financial success of your product.

Overall guidance

Like many of you, we were a ‘Start-up’ only five short years ago. At Urtech, we completely understand the challenges associated with launching a new company while launching new products. Not only have we helped independent start-ups, within our facility, we have allocated space for small start-up companies to develop products and conducted proof-of-concept activities. By following these steps and by seeking more product specific guidance then your launch could be quite straightforward. If you need any help, please feel free to reach out.