Manufacturing SMARTer

By Stephen Law, Editor EP&T

Automation / Robotics Electronics Contract Manufacturing automation CEM contract manufacturing Dorigo Editor Pick EMS factories Industry 4.0 Manufacturing Simon-Frazer smart universityDorigo Systems and Simon Fraser University forge innovative partnership to unlock potential of Smart factories

Dorigo Systems, a Burnaby B.C. based contract electronics manufacturing firm, has embarked on a trailblazing collaboration with Simon Fraser University (SFU) to spearhead the integration of Industry 4.0 technologies within the electronics manufacturing sector. With funding support from MITACS, this innovative partnership aims to revolutionize production systems, while nurturing the next generation of engineers to thrive in the era of smart factories.

The focus of this collaboration between SFU and Dorigo is to prepare the next generation of engineers who will have the specific skill set needed to tap into smart factories. SFU’s Mechatronic Department is driving forward in creating a graduate program that will build a strong base of talent within the local economy.

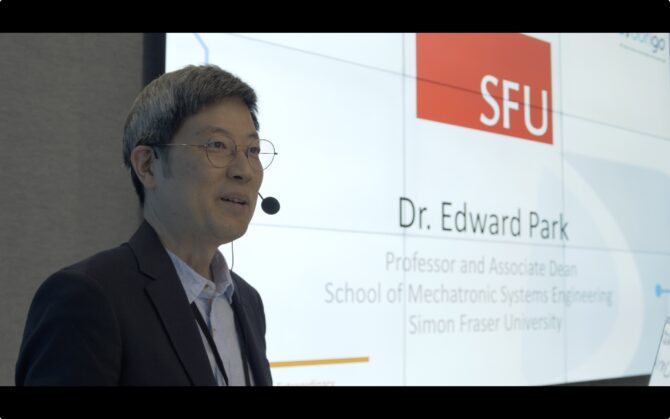

Dr. Edward Park, PhD, P.Eng. and Professor and Associate Dean, School of Mechatronic Systems. Source: Dorigo Systems

“A few years ago, I noticed the opportunity to offer a new Masters of Engineering program in smart manufacturing and systems. As well, we wanted to create a research program or project on sort of a similar topic of industry 4.0,” explained Dr. Edward Park, PhD, P.Eng. and Professor and Associate Dean, School of Mechatronic Systems.

Leveraging approval from federal government funding programs and existing relationship ties with Dorigo, both parties began working closely together in terms of transforming the rigors of a production line into being more server industry 4.0 Smart manufacturing oriented, according to Park.

Opportunities in paradigm shift

The rise of Industry 4.0 has propelled the electronics manufacturing industry to the forefront of innovation. By fusing data-driven intelligence with manufacturing processes, a transformative potential to streamline and enhance operations has emerged. Recognizing the immense opportunities presented by this paradigm shift, Dorigo Systems and SFU have joined forces in hopes of reshaping the landscape of agile manufacturing.

The collaborative research leans into exploring and validating Industry 4.0 concepts across Dorigo Systems’ manufacturing processes. By integrating advanced technologies such as artificial intelligence, Internet of Things (IoT), cloud computing, and big data analytics, this research aims to enhance productivity, flexibility, and agility within the electronics manufacturing value chain.

The synergy between Dorigo Systems and Simon Fraser University is setting new benchmarks for academic-industry alliances by unlocking the potential of Industry 4.0 and smart factories. Source: Dorigo Systems

“There has been a lot of noise in the recent years regarding industry 4.0 and how it proposes to transform a lot of things. But, what does that really mean for us? I recognized some unique opportunities for CEMs like ourselves, where we deal with a lot of batch based manufacturing, not necessarily the traditional straight, long assembly line where you know, we have all these workstations from one to the next to the next,” says SFU alumni Kin Leong, now senior project manager at Dorigo Systems. “We want to add to that Industry 4.0 knowledge pool and this is where we see a lot of opportunities working with SFU in building this relationship.”

SFU, renowned as Canada’s top university for innovation in global rankings, has recently launched its Smart Manufacturing Hub, positioning itself at the forefront of cutting-edge research. This year, SFU has been named as Canada’s top university for innovation in global

WURI rankings in 2023. As part of this new collaboration, SFU’s Mechatronic Department is spearheading the development of a graduate program to equip future engineers with the specialized skill set required to harness the full potential of smart factories, enriching the local economy with a talent pool tailored to Industry 4.0 demands.

Central to this partnership is a multifaceted research initiative aimed at exploring and validating Industry 4.0 concepts throughout Dorigo Systems’ manufacturing processes. Integrating advanced technologies like artificial intelligence, the Internet of Things (IoT), cloud computing, and big data analytics, this collaborative effort seeks to optimize productivity, flexibility, and agility within the electronics manufacturing value chain.

How do the next 10, 30-years look

“An essential part of industry 4.0 is incorporating such things as AI, new sensors and robotics and more,” notes Park.

A key area of investigation revolves around the application of additive manufacturing in electronics production. Leveraging 3D printing technologies, Dorigo Systems and SFU are pioneering rapid prototyping and on-demand manufacturing of electronic components. By adopting additive manufacturing, the partnership aims to streamline production, reduce waste, and elevate design flexibility, thereby accelerating time-to-market and fostering innovation and sustainability.

“With 35-years of operational history behind us, we’ve learned a lot of things that didn’t work well,” Leong says. “But, what does the next five, 10 or even 30-years look like for this industry? We’re in a very, very dynamic time right now, with emergence of a lot of new technologies. Not to mention how millennials and Gen X or Gen Z’s work very differently in a workforce. So, working with SFU students, and conducting this level research is really kind of exploring what some of the ideas out there that can have short term and long-term benefit for us at Dorrigo.”

Additionally, the integration of collaborative robots, colloquially known as ‘cobots,’ is at the forefront of exploration. Dorigo Systems and SFU are jointly researching the optimal deployment of cobots on the assembly line, automating repetitive tasks, enhancing precision, and ensuring consistent quality. This collaborative human-robot interaction not only boosts efficiency but also fosters a more ergonomic work environment, amplifying the overall productivity of human operators.

The collaborative research leans into exploring and validating Industry 4.0 concepts across Dorigo Systems’ manufacturing processes. By integrating advanced technologies such as artificial intelligence, Internet of Things (IoT), cloud computing, and big data analytics, this research aims to enhance productivity, flexibility, and agility within the electronics manufacturing value chain.

Cutting-edge collaboration

“At Dorigo, we have a huge level of automation that we use, but there’s a whole half of the factory that is very manual and people based. Frankly, there’s nothing that beats the dexterity of a human being at this point. And, I don’t care that a lot of roboticists that will always disagree with me on that. But, I still see that in practical industry, especially in contract manufacturing, human beings are the most versatile and flexible in most agile resources,” enthused Leong. “Having said that, I think we can we actually bring collaborative, cooperative robots to that level. There is potential there, but that still needs wor.k”

The ramifications of this cutting-edge collaboration extend far beyond Dorigo Systems’ operations. As insights gained from this research influence and inspire the wider industry, the future of manufacturing is poised to be redefined. By embracing Industry 4.0 technologies and leveraging their joint expertise, Dorigo Systems and SFU are trailblazing a path towards greater operational efficiency, sustainability, and competitiveness in the electronics manufacturing sector.

“From SFU side of things, it’s all about training the next generation of engineers and manufacturing engineers. It’s about developing a skill or training and deploying bright minds for a better future for Canada, and for BC. By doing so, we strengthen Canada’s innovation ecosystem and manufacturing ecosystem. This, of course, puts Dorigo at the forefront of all those things,” Park says.

Agile manufacturing

Through their joint efforts, Dorigo Systems and SFU are paving the way for a future where flexible and agile manufacturing becomes the new standard in the electronics manufacturing industry. By embracing Industry 4.0 technologies and leveraging cutting-edge research, they are not only enhancing operational efficiency but also innovating new ways of manufacturing.

As this transformative partnership continues to make strides, the synergy between Dorigo Systems and Simon Fraser University is setting new benchmarks for academic-industry alliances. By unlocking the potential of Industry 4.0 and smart factories, they are poised to revolutionize the electronics manufacturing landscape, fueling progress and innovation that will resonate well beyond the confines of their collaboration.

“Electronics manufacturing needs to embrace smart factories, in terms of improving efficiency adding agility, enhancing quality control and flexibility. However, we have a shortage of skilled workers to make these transformations. So, that’s an area that where universities like SFU, and UBC can can come in and help by working in partnership – we can actually train these skilled people together,” Park concludes.