Internet of never-ending things

By Brad Rex, director, system and solutions, Renesas Electronics

Electronics IoT Electronics embedded IoT systemsIs it possible to stay ahead of the continuous design cycle?

Intro:

Hardware design. Software implementation. Cloud integration. AI/ML. Security. Over-the-air updates. Modern IoT designs are massively complex, requiring a much broader engineering skillset than just a decade ago. This makes development a daunting task. Reduced personnel with tighter deadlines may force one to drop features and cut corners to get to market on-time. But, software and design tools exist on the market to accelerate all parts of the design cycle from concept to hardware fabrication. In many cases, these tools require zero knowledge of hardware or software design. In this article we will explore how these design tools are evolving to assist engineers to develop efficiently and at a faster rate.

~~~~~~~~~~~

Modern design of embedded electronics systems is easier than ever. Depending on the design’s complexity, you can design, validate, and have prototype hardware samples on hand in just a matter of weeks, if not days. Even though designs are becoming increasingly complex, many of the tools, software/hardware modules, and cloud connection schemes have standardized to a point where much of it can be automated but still provide a level of uniqueness for each IoT design. In this article, we will look at how the design paradigm is shifting to provide more value and reduce time to market, while simultaneously trying to reduce the workload and demand of engineers.

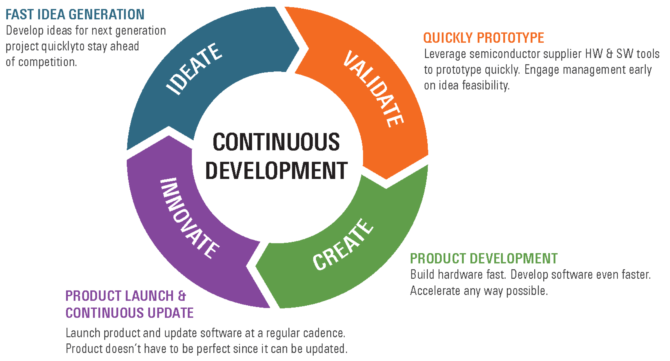

In just the past two decades, we have seen a huge shift in hardware design processes. These shifts have allowed for a continuous development philosophy, where fast idea generation can be proven out quickly and turned into a product much faster than before. Previously, designs were often bespoke, tailored for the exact specification, form, and fit for a particular design. Software development could often not be started until after hardware was fabricated and assembled, effectively linearizing the design cycle. And if the hardware did not work or a workaround could not be implemented, that increased the project timelines for a re-spin.

Complete SoM or SBC

Then, hardware got cheaper to produce, and it could be manufactured very quickly anywhere in the world. The platform design concept, where a single pcb design could be populated and depopulated to serve different product definitions, became the easiest way to develop a family of products. Combining this with the Internet, open source, sharing, and community involvement reduced the investment needed to quickly try out a new idea, or even to put a product into market.

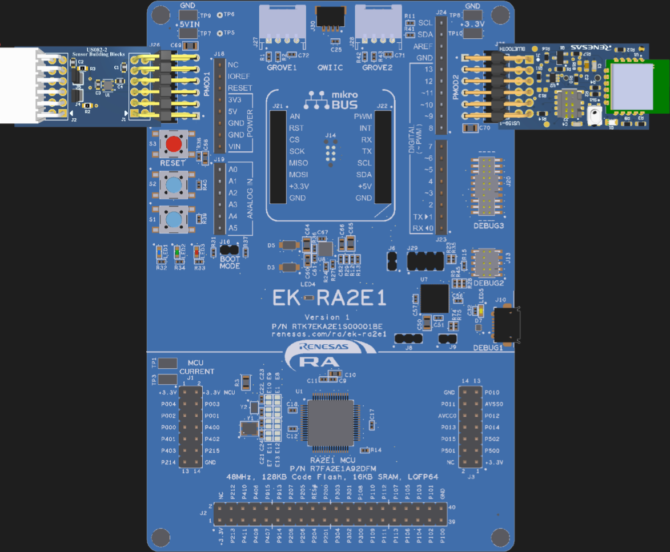

Single-board computers (SBCs), such as Arduino and Raspberry Pi became household names in the engineering community, and System on Modules (SoMs) gave users access to a wide feature set with little to no hardware investment and only a small price premium when purchasing the complete SoM or SBC. While it would not be recommended to go to market with a community-styled SBC (supply chain issues, over-specified, and higher cost), it could be possible in smaller volumes, and many products are in the market today using them.

Taking this modular development approach a step further, tools exist on the market today that automate the system design approach to actual hardware development. Tools such as the CELUS Design Platform allow you to systematically create your design from logical units in a hardware design (processor, sensors, wireless connectivity, LEDs, power rails, etc.), select potential component candidates for these blocks from vendors of your choosing, and then automatically create an EDA package with those exact parts and that exact design. In another example, Upverter from Altium allows you to take pre-developed hardware modules and drag and drop them into a design. Once signals are hooked up properly, Upverter will compile your EDA project and can even send it out for manufacturing and assembly. This may not be as fast as one-click buying from one of the world’s largest e-commerce websites, but we are approaching that level of automation and sophistication.

Software development has also gone through its own cycle of reuse and modularity but did so much earlier than hardware. Open-source initiatives were the first to put large pieces of software into the hands of developers with little to no cost. Collaborative and distributed software design and repositories like GitHub further aim to bring together many disparate groups and people across the globe to work together on solving challenging software designs.

Determine spatial motion context

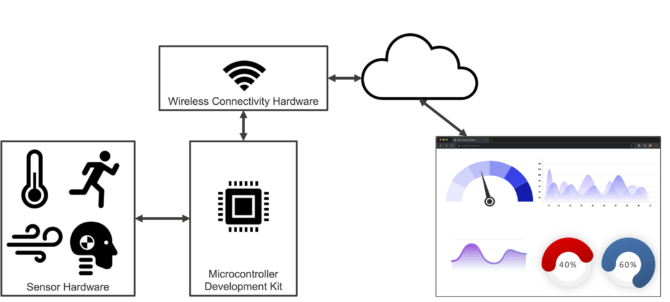

Some companies are now trying to glue together modular hardware and software design. In the DevOps IT world, low code and zero code methodologies, where you drag and drop your system flow together with very little code development effort, have been the norm for many years. This mentality is starting to bleed over into product design, where companies are building workflows that allow you to put together hardware module blocks like development kits, modules, SOMs, and SBCs and then automatically apply appropriate code for that system. Quick-Connect Studio from Renesas is such a tool, allowing you to drag and drop hardware components together. The online browser environment allows users to graphically visualize their system just like the real development hardware they have, and then automatically create a software application project with those exact components.

As an example of how this would translate to a real-world application, let’s assume you pull together a microcontroller, Bluetooth LE connectivity, and a 6-axis inertial motion sensing unit. It would be logical to think that this system wanted to determine spatial motion context and send that data to a mobile phone application. The base software would automatically be constructed to perform this task, shifting the engineering lift from low-level coding of drivers and Bluetooth Low Energy profiles to developing a better user experience with a mobile app or doing additional sensor fusion or machine learning.

In another example, if a microcontroller was paired with Wi-Fi connectivity and an air-quality and temperature sensor, this system is operating very similar to a weather or air quality monitor. This data would be sent to a cloud service provider over Wi-Fi where it could be analyzed and then pushed down to mobile phones that are subscribed for updates. The point with these two examples is that the low-level software for reading sensor data, formatting it, and sending it to a server is not novel and unique. That problem has been solved many times over, so it should be automated, thus freeing the engineer to work on other, more complex tasks.

ChatGPT can already produce code

The next big thing everybody is talking about across many industries is ChatGPT and large language models. ChatGPT is in its infancy, but it is conceivable that it could design hardware and software for you with not much more than a descriptive language of what problem we were trying to solve. Assuming ChatGPT was properly trained with datasheets, hardware user manuals, and design and manufacturing rules, ChatGPT could produce quality hardware designs based on descriptive documentation, and potentially with fewer errors. The same goes for software. ChatGPT can already produce code, but if it was fed with your coding standards and if it had already analyzed how drivers and middleware components were coded for your system, the ChatGPT engine could easily create code that had the same style, look and feel, and software design paradigms that your company designs for today. As people start to expand ChatGPT in time-saving ways, it will only be a matter of time before hardware and low-level software design can be completed automatically, allowing engineers to focus on other aspects of their product to create value and drive business.

We are in a golden era of electronic design. With reduced effort, engineers have many tools at their disposal to accelerate the design of hardware and the accompanying software. Within the next few years, ChatGPT and large language models will play an even bigger role in this space, but the overall goal is the same. Engineers should spend less of their time on the basics of hardware and software product design and instead automate and reduce their efforts on these tasks while refocusing their effort on value-add or features that can drive better customer engagement and more product sales.

————————————-

Renesas is a global leader in microcontrollers, analog, power and SoC products, delivering trusted embedded design innovation to shape a limitless future.