How to decipher self-clinching fastener codes

By Christa Carey, manager of technical support, Protocase

Electronics Production / Materials Engineering enclosures hardwareProtocase breaks down these hardware pieces for enclosures

Self-clinching fasteners are a crucial part of custom sheet-metal enclosures and parts. They solve many challenges for mounting components. Plus, self-clinching fasteners provide high push-out and torque-out resistance, as well as strong threads in very thin material. Since self-clinching fasteners have fewer parts, you do not require extra hardware such as washers and loose nuts for final assembly. This gives you a streamlined design with less overall assembly time (and, by extension, low installation costs).

You’ve probably heard of these fasteners being referred to as their abbreviation PEM – that comes from Penn Engineering & Manufacturing Corp., which is the world’s leading manufacturer of self-clinching fasteners.

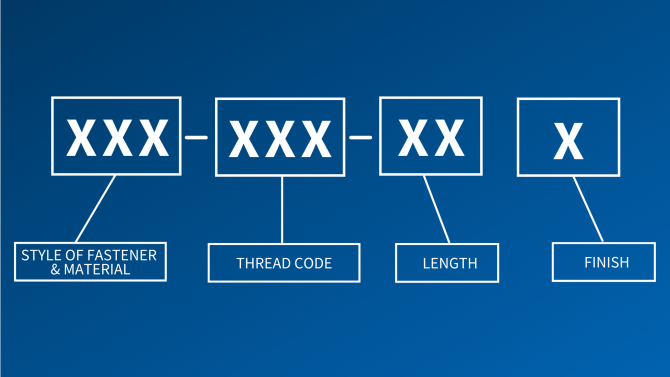

If you’ve ever looked at a part number for a self-clinching fastener, you likely have noticed the series of letters and numbers within the part number. This blog post will go through each portion of the part number, and decipher the codes that are associated with the self-clinching fasteners so that you can quickly decide on the best fastener for your specific needs.

Pictured here is a diagram of how each self-clinching fasteners name is broken down. Starting off in the left box is the style of fastener & material, in the middle is the thread code, followed by the length and finish.

Styles of Fastener & Material

Our most popular self-clinching fasteners are nuts, studs and standoffs.

Nuts

Self-clinching nuts.

There are six different codes associated with nuts: Carbon Steel Nut (S -) & (SS -), 300 Series Stainless Steel Nut (CLS -), 400 Series Stainless Steel Nut (SP -), Aluminum Nut (CLA -), Flush Nut (F -).

So, for example when figuring out the code for the self-clinching fastener, if you were using an Aluminum Nut, the first part of your code would be CLA.

Code in Fastener Name Meaning

S – Carbon Steel Nut

SS – Carbon Steel Nut

CLS – 300 Series Stainless Steel Nut

SP – 400 Series Stainless Steel Nut

CLA – Aluminum Nut

F – Flush Nut

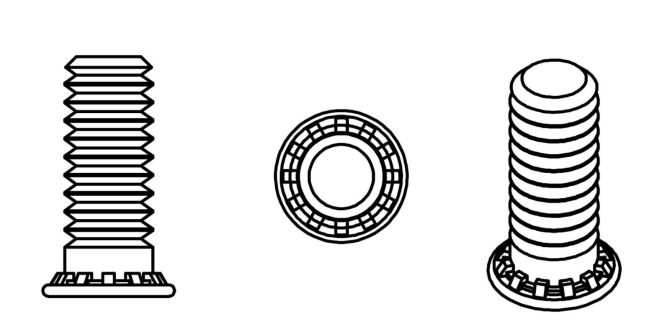

Studs

Studs

There are three different codes for studs. They include Carbon Steel and Flush Head Stud (FH -), 300 Series Stainless and Flush Head Stud (FHS -), 400 Series Stainless and Flush Head Stud (FH4 -).

Code in Fastener Name Meaning

FH – Carbon Steel, Flush Head Stud

FHS – 300 Series Stainless, Flush Head Stud

FH4 – 400 Series Stainless, Flush Head Stud

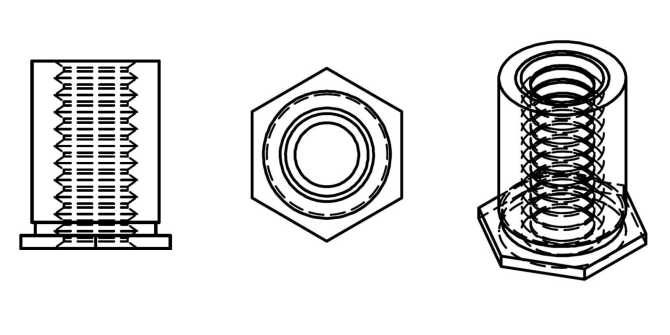

Standoffs

Self-clinching standoffs.

Similar to nuts, self-clinching standoffs also have six different material codes: Carbon Steel and Thru-Hole Standoff (SO -), 300 Series Stainless and Thru-Hole Standoff (SOS -), 400 Series Stainless and Thru-Hole Standoff (SO4 -), Carbon Steel and Blind Standoff (BSO -), 300 Series Stainless and Blind Standoff (BSOS -), 400 Series Stainless and Blind Standoff (BSO4 -).

Code in Fastener Name Meaning

SO – Carbon Steel, Thru-Hole Standoff

SOS – 300 Series Stainless, Thru-Hole Standoff

S04 – 400 Series Stainless, Thru-Hole Standoff

BSO – Carbon Steel, Blind Standoff

SOSOS – 300 Series Stainless, Blind Standoff

BSO4 – 400 Series Stainless, Blind Standoff

Thread Code

Moving on, we have the second part of the code and that is the Thread Code. The Thread Code identifies the internal or external threads for the self-clinching fasteners. They will be either imperial or metric.

Usually, the code will be the same as the thread but just without the “-“. For example, a 4-40 threaded self-clinching fastener would be XXX-440-XXX).

The most common threads used are: 4-40; 6-32; 8-32; 10-32; 10-24; 1/4-20; M3; M4; M6.

Length Code

Length code indicates the length of the standoff or stud, or it indicates the length of the shanks for self-clinching nuts.

TIP: Self-clinching fasteners with a Zinc finish will have “Zi” after the length code (XXX-XXX-1Zi).

Nuts

The length code for self-clinching nuts indicates the length of the shank. Typically, the longer the shank, the more force required to knock the fastener out of place. However, when the shanks length increases, the fastener’s minimum sheet thickness increases as well. Nuts have four different shank codes, as detailed below in the table.

Shank Code Minimum Sheet Thickness

-0 0.030”

-1 0.040”

-2 0.056”

-3 0.090”

Studs

The length code for studs is measured in 1/16″ increments for imperial fasteners and millimeters for metric fasteners. The length of the stud is its actual length. Studs have three different length codes.

For imperial, with a fractional length of 4/16″ (1/4″) and a decimal inch length of 0.250″ the length code would be -4. For a fractional length of 6/16″ (3/8″) and a decimal inch length of 0.375,” the length code is -6. Lastly, if the fractional length is at 8/16″ (1/2″) and at 0.500″ for decimal inch length, the length code would be -8.

Things change for metric fasteners. If the stud length was 6mm and decimal inch length was 0.236,” then the length code would be -6. For an 8mm stud length and decimal inch length of 0.315,” the length code is -8. Finally, if your stud length reached 10mm and decimal inch length was 0.394,” the length code would be -10.

Imperial

Length Code Fractional Length Decimal Inch Length

-4 4/16” (1/4”) 0.250”

-6 6/16” (3/8”) 0.375”

-8 8/16” (1/2”) 0.500”

Metric

Length Code Fractional Length Decimal Inch Length

-6 6mm 0.236”

-8 8mm 0.315”

-10 10mm 0.394”

Standoffs

The length codes for standoffs are measured in 1/32″ increment for imperial fasteners. Just as with studs, metric standoffs length code is measured in millimeters and is the actual measurement of the fastener.

For imperial if the fractional length is at 10/32″ (5/16″) and decimal inch length is 0.312″ then the length code would be -10. For a fractional length of 12/32″ (3/8″) and decimal inch length of 0.375″ then length code is -12. A length code of 14/32″ (7/16″) and 0.437″ for decimal inch length the length code would come to be -14. Lastly, if the fractional length is long as 16/32″ (1/2″) and decimal inch length of .500″ then length code would come to be -16.

Moving to the metric side of things, if the standoff is 6mm of length and 0.236″ of decimal inch length, the length code is -6. A standoff length of 8mm and decimal inch length of 0.315,” the length code is a -8. Finally, if the standoff length is 10mm and 0.394″ in decimal inch length the length code is -10.

Imperial

Length Code Fractional Length Decimal Inch Length

-10 10/32” (5/16”) 0.312”

-12 12/32” (3/8”) 0.375”

-14 14/32” (7?16”) 0.437”

-16 16/32” (1/2”) 0.500”

Metric

Length Code Fractional Length Decimal Inch Length

-6 6mm 0.236”

-8 8mm 0.315”

-10 10mm 0.394”

Finishes

Self-clinching fasteners can either be unfinished, or treated with a finish, plating or coating. These finishes not only provide aesthetic advantages, but can provide a certain level of corrosion resistance. Here are the types of plating codes you will see as a suffix at the end of the fastener code:

Zinc Plating

- Zinc Plus Clear Hexavalent Free Chromate – Part Suffix ZI

- Zinc Plus Yellow Hexavalent Free Chromate – Part Suffix ZC

- Zinc Plus Clear Trivalent Chromate Plus Sealant/Lubricant – Part Suffix LZ

- Zinc Plus Other Chromate Conversion Coatings – Part Suffix ZB & BZ

Nickel Plating

- Bright Nickel Over Copper Flash – Part Suffix CN

- Electroless Nickel Over Copper Over Nickel Strike – Part Suffix NC

- Semi-Bright Nickel – Part Suffix N

- Semi-Bright Electroless Nickel – Part Suffix EN

Electro-Tin/Solderable Platings

- Electro-Tin With Clear Preservative Coating – Part Suffix ET (DT)

- Electro-Solder – Part Suffix (ES)

Dry Film Lubricants

- Carbowax – Part Suffix CW

- Molybdenum Disulfide Dry Film Lubricant – Part Suffix MD

- Solid Film Lubricant (Used On M45938/7 And M45938/11 Locknuts)

Cadmium Plating

- Cadmium Plus Clear Chromate – Part Suffix CI

- Cadmium Plus Metric Blue Chromate – Part Suffix CB

- Cadmium Plus Olive Drab Chromate – Part Suffix CO

- Cadmium Plus Yellow Chromate – Part Suffix C

- Cadmium Without Finish Coat – Part Suffix CD

Black Nitride

Black Nitride And Dry To Touch Oil – Part Suffix BN

Conclusion

One handy tip for remembering the parts of a self-clinching fastener code: Just remember the abbreviation STL: Style of Fastener & Material; Thread Code; Length.

Self-clinching fasteners are one of the most useful hardware components at a designer’s disposal.

————————–

Christa Carey was the first employee hired by Protocase when the company was formed in 2002. Christa manages a team of engineers and technologists in the CNC Machining Division.