How Interpower Corporation cable is made

EP&T Magazine

Electronics Engineering cable colours cords custom-made electrical Interpower resins wire

Sponsored by Interpower Corp.

Before cord sets are ready to be boxed for shipping, the colourants used in the resins, and the shiny brass and alloys of blades and pins may often resemble an electrical work of art that catches the eye—especially the orange and red cord sets preferred by Australian and Denmark hospitals respectively. Or maybe it’s a clear molded plug, or a hand-wired plug where one can see inside to tell whether every wire retains electrical continuity around the stainless steel ring that binds the conductors. Even standard colours like black and gray offer a semblance of eye candy while manufactured to carry hundreds of volts to equipment across multiple environments.

These finished electrical products began as reels of copper, pellets of resin, stainless steel or alloy screws and fasteners, folded brass and other alloys, bridges, strands of Kevlar, fuses, and the multiple processes on multiple machines to extrude (insulating and jacketing), cable (in part via a rotating capstan), mold, cut, strip, crimp, ultrasonic weld (metal and plastic), label, hank, and tie. There are also numerous stations along the way just on the extrusion line: multiple laser-measuring stations, a wire-cleaning station, extruders 1-3, a talc station, spark testers, a water-cooling station, and a drying station.

Everyday marvels

Inventions that changed the world are too numerous to list: fire, the wheel, gun powder, the printing press and the steam engine, the pencil and the light bulb, and likely somewhere down the list is the bare copper wire. Copper is an iconic conductor with many great properties—corrosion resistance is high among them, and copper is still a popular conduit for water.

The extrusion line: A magical mystery tour

Join Interpower’s own, Brady Brown, and get a special video tour of our cable manufacturing.

One reel at a time, the copper conductor wire unspools with the aid of a clipper lift inside a ‘bug eye’ which allows the wire to unspool its hundreds of pounds while keeping square to the extrusion line. The unspooling of cable down the line relies on a tensioner on one end and a take-up or accumulator on the other end to maintain the necessary tension as to complete the extrusion process.

As the bare wire speeds down the line up to 1,000 feet per minute, its diameter is continually measured by multiple readers using lasers integrated with computer hardware and software which measure to 1/10,000 of an inch. The bare copper wire is cleaned along the line before being extruded in resin by extruders 1-3. Extruder 1 contains the natural, light-coloured material while extruders 2 and 3 extrude separate colours such as blue and brown to coat the bulk of natural resin material from extruder 1—colours are alternated from extruder 2 to 3 by turning a switch on the crosshead.

Measured before and after extrusion

The insulated wire is measured before and after extrusion while ‘hot’ and measured after cooling ‘cold’ once immersed in a water trough via a filtrated chiller. Laser measurements are taken multiple times along the extrusion line to meet worldwide agency standards (diameters).

The various colours designate ground, line, and neutral conductors according to North American, international, and Japanese colours per their agency standards. However, four- and five-conductors may be required for larger cable diameters, requiring even more natural resin from extruder 1 during the jacketing process. The insulated wire maintains agency diameter specifications due to the laser measurements which regulate and adjust in concert with dry and wet capstans, which are vertical drums spinning the cable faster or slower to reduce or add material to meet preprogrammed diameter specifications.

Bare copper is never spark-tested due to the nature of copper and electricity, but once insulated, the wires are spark-tested for holes or gaps in the natural material.

Jacketed wire (cable)

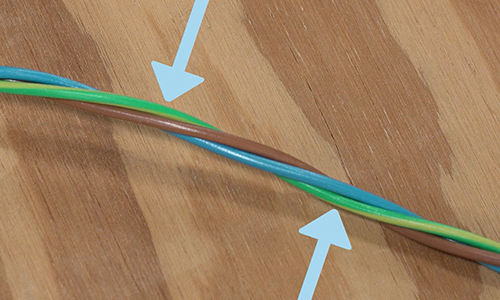

Once the separate insulated wires spool onto the take-up, the individual spools run through the rotating capstan connected to the cabler, and strands are ‘bunched’ into a length of lay: the length of one coloured wire woven under another coloured wire (visible to the eye) is one definition of the length of lay. The length-of-lay makes the bunched wires more flexible which helps preserve the electrical continuity of its conductors.

Arrows point out Green/Yellow Ground Wire length of lay.

Before being jacketed, the bunched length-of-lay conductors are coated in talc (for easier wire-stripping by the customer) before being jacketed in natural resin and a single layer of colourant. Extruder 1 is the workhorse for jacketing since cable requires much more natural resin than colourant to hold the conductors in place while remaining flexible. The single layer of colourant is added onto the wall of the cable for identification (line, neutral, ground, etc.).

The jacket runs through a printer down the line to receive agency (UL/CSA/VDE, etc.) file numbers and approval marks, voltage and flammability ratings, jacket material, e.g., ‘SJT’ and sizes in AWG and mm along with the manufacturer (Interpower). The cable is now ready to be spooled onto a wooden reel where it is wrapped in plastic and properly labeled. The cable is now ready to be shipped.

Like this article? Get more like it by signing up for our monthly newsletter!