Derating of medical power supplies

By Dermot Flynn, director of strategic marketing, medical power products at Advanced Energy

Automation / Robotics Electronics Power Supply / Management Medical equipment medical power suppliesConsistent challenges faced by medical equipment manufacturers

A consistent challenge faced by medical equipment manufacturers is rising system functionality, improving technical performance, increasing reliability, while reducing size. This is a common challenge across a wide range of medical applications including medical imaging, life science, electrosurgery, patient care and monitoring for use throughout the world.

The engine room of all these systems is the power conversion. The power supply or power supplies, converting ac to dc, as well as the dc-to-dc conversion required throughout the system are critical enablers. In response to customer demands, there is increased market pressure on power supply designers to develop solutions with higher power density without compromising on reliability or performance.

However, while reducing the size of a power supply, component temperatures must be kept low to ensure long term reliability of the medical equipment. More importantly, patient, doctor and clinician safety are paramount and non-negotiable.

What is derating?

If a power supply could convert all the power entering it to useable power output, it would be 100% efficient. However, a certain amount of energy is ‘lost’ during each conversion stage as it converts from one voltage level to another. Any inefficiency in a power supply will be converted to heat which both affects the long-term reliability of the power supply as well as the system.

Derating is a practice of reducing the output power rating of a power supply based on the input line voltage and/or the operating air ambient temperature to alleviate a rise in component temperature and ensure that the thermal limits of safety critical components are not exceeded.

Line voltage derating

Medical equipment and device OEMs develop systems that will be used throughout the world for patient treatment and diagnoses. There are various standard global ac input line voltages, and these can range from 100Vac in Japan to 240Vac in Australia (with many other ‘standard’ line voltages in between such as 115, 220 and 230Vac). Systems designed for worldwide operation must have an input voltage range that is rated for use across these line voltages. Additionally, there is increasing numbers of medical systems being deployed in the developing world and in more remote locations, which may need to operate at even lower line voltages, such as 85Vac or 90Vac, due to line disturbances or brownouts. Irrespective of location and anticipated line voltage variations, the medical systems MUST provide accurate results and operate reliably and safely.

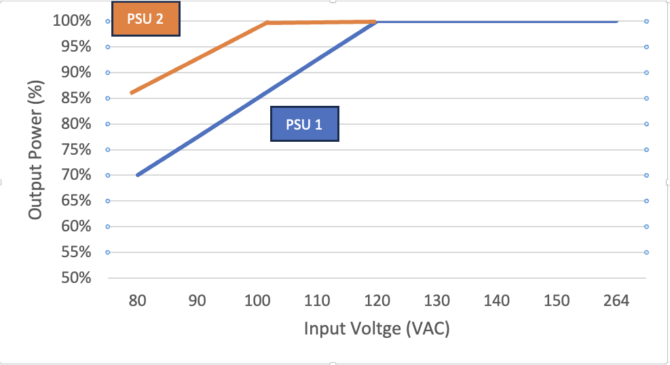

It is not unusual for manufacturers to specify the power rating of a power supply at 110Vac or even 120Vac, so particular attention must be paid if the system is to operate off a line voltage lower than these. The input power derating can be quite significant when operating at 90Vac.

See the example Above.

* PSU 1 is rated at 600W when used at 120Vac or higher.

* PSU 2 is rated for 600W from 100Vac or higher.

* If you follow the curve, you will see that PSU 1 can deliver 78% (465W) at 90Vac, whereas PSU 2 can deliver 92.5% (or 555W).

It is important to remain aware of this when selecting the power supply. At first glance, using the headline figures of 600W, the power density of PSU 1 may look better, however, if you require the system to operate globally, you may need to select a higher power version of the product.

Input line voltage derating is used to alleviate overheating of the power supply (such as the input filter & PFC boost converter) at higher input currents. Some losses are linear in relation to the input current, however, other losses such as those in EMC chokes increase by the square of the current, thereby generating even more heat.

For equipment designed for worldwide use, it is imperative to select a power supply with the appropriate low line voltage rating, thereby improving long term reliability.

Temperature derating

Medical equipment was traditionally located in a hospital environment. However, increasingly, equipment is being used in clinics and doctors’ offices as well as ambulances, temporary clinics, and the home. The temperature environments that equipment must operate in can vary from a tightly controlled air-conditioned operating room, to warmer, high humidity environments, but in all cases, the equipment must perform safely, accurately and reliably.

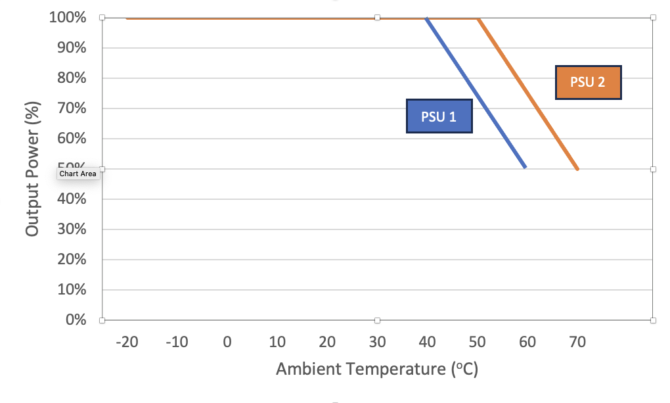

Temperature derating is used to ensure component temperatures do not exceed the specifications, operate reliably, and comply with safety requirements. Most power supplies have a derating curve based on temperature. In the case of open frame, convection cooled and fan cooled power supplies, the temperature rating refers to the ambient temperatures (the air temperature around the power supply). For conduction cooled power supplies, it may also refer to a base plate temperature (the heatsink or plate the power supply in mounted on).

In some cases, manufacturers limit the maximum ambient temperature for full power operation from 40C derating to 50% at 70C (or even 60C). Therefore, it is of critical importance to understand the temperature derating of the power supply selected as well as the true operating ambient temperature that it will be subjected to.

The graph above illustrates temperature derating curves of two open frame power supplies. * PSU 1 delivers 100% power at 40C and derates to 50% at 60C * PSU 2 delivers 100% at 50C and derates to 50% at 70C.

Open frame power supplies are built into a system, where air ambient inside the system is often 10C higher than the ambient temperature around the system. This must also be considered when selecting the power supply for the system.

For example, a system is specified to operate in an ambient temperature of 40C and requires 500W of power to perform its operations. Remembering the internal temperature will be 10C higher, the air ambient around the power supply could be up to 50C. Using the graphs above for a 600W power supply, PSU 1 can deliver 75% (450W) of rated power at 50C, whereas PSU 2 can deliver the full 600W. The headline specification figures of PSU 1 can suggest a high-power density and smaller size, however, when examined more closely, it would be inadequate to meet the true needs of the system.

Conclusion

Actual power ratings can be underestimated dramatically depending on the actual operating conditions of the power supply and require derating. Further, system manufacturers also apply their own derating, often specifying all components should only be used at 90% or even 80% of their full ratings.

In the examples above, at 90Vac and 50C, PSU 1 can deliver 351W, where PSU 2 can deliver 555W. Applying the additional derating defined by the system manufacturers, further reduces the “available” power from the power supply. Power supplies such as the NGB series from AE, are designed specifically to minimise derating at low input line voltage as well as operating in ambient temperatures up to 70oC, providing greater margin in performance. This ensures that system designers can meet their challenges of increased performance with improved long-term reliability.

It is important to note that power supplies will not limit the available power at the output and will continue to operate. However, they may be operating outside the power supply derating curves, which will have a significant impact on product lifetime and reliability. Product safety may also be compromised if component thermal limits are exceeded, particularly at isolation barriers.

While the drive for reduced size and higher power density will continue, factors such as product performance, reliability and safety cannot be compromised. As power supply sizes are pressed to be smaller and smaller, the key to maintaining reliability is a combination of reducing losses and effectively dealing with heat flowing away from key components. It is critically important to pay close attention to both the line voltage and thermal deratings of a power supply when selecting for a medical system to ensure long term reliability, safety and performance.

——————————

Dermot Flynn is the Director of Strategic Marketing, Medical Power Products at AdvancedEnergy. In his 20 years in the power supply industry, Dermot has held a number of senior roles in product development, product & technical marketing, and sales. Dermot holds a BAI in Electronic and Electrical Engineering and a BA in Mathematics from Trinity College, Dublin, as well as a Higher Diploma in Management & Marketing from University College, Cork, and an H-Dip in Education from Trinity College, Dublin.

https://slpower.com/ngb-series-sample