Component traceability and transparency are essential for success

By Teri Ivaniszyn, vice-president, operational excellence, Digi-Key Electronics

Electronics Supply Chain chain component counterfeit distribution Editor Pick supply traceability transparencyEspecially within the electronic parts distribution ecosystem

The electronic components supply chain has evolved immensely over the past few years. That’s a good thing, but it also comes with challenges that are driving the need for greater accountability and transparency. These challenges include increased outsourcing to global counterparts and a rise in counterfeit activity.

Many companies are understandably desperate to find the chips they badly need, and as a result are turning to new – and sometimes untrustworthy – sources to find them. With the supply chain under immense strain due to shortages of all kinds, including semiconductors, there has unfortunately been a flood of counterfeit products entering the market.

Source: Adobe Images

These parts may appear very similar to the authentic version, or even be refurbished components that are sold as new. It can sometimes be difficult to tell the difference, with little details such as packaging or a ‘not-quite-right’ appearance giving away the inauthenticity. Other times, the differences are undetectable without sophisticated technology.

These black-market schemes can be widespread, and can generate millions of dollars in revenue. A bad actor in the U.S. was recently sentenced to two years in prison and a $250,000 fine for conspiring to sell counterfeit smart phone components.

So how can you protect your company from falling victim to these costly and frustrating counterfeits? The key lies with traceability.

Traceability is key

Reputable distributors are addressing counterfeit challenges while working to retain existing customers and attract new ones by providing traceability information, including date codes, and lot and serial numbers. Given the rise in counterfeit inventory, customers want to know where their products are manufactured and what they’re made of.

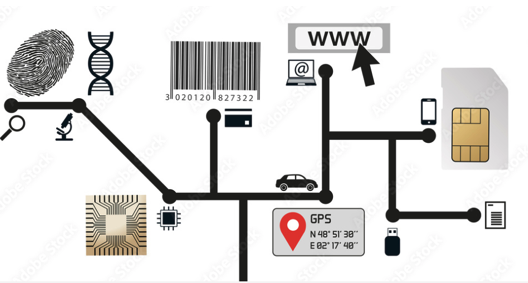

Traceability technologies enable manufacturers to track production information back to the exact date, time, supplier components, operator and machines used.

Source: Adobe Images

This and other such information enables anyone throughout the supply chain to trace components back to the original equipment manufacturer (OEM) should anything go wrong. Within the electronic components industry, specifically, traceability is quickly becoming a priority.

Companies slow to provide traceability for their components are likely to fall behind, quickly losing credibility and even market share.

Advantages of traceability

Advantage #1: Combats counterfeit activity. In the last few years and especially with shortages hamstringing the supply chain, the electronic components industry has seen an uptick in counterfeit components flooding the market. The industry is responding by developing new processes to increase transparency and traceability for authentic parts within the supply chain.

Advantage #2: Helps mitigate product recalls. Product recalls are common—and expensive—so protecting your company against such recalls and the associated liability is critical. In the event that a recall does become necessary, having robust traceability data helps you manage the recall more quickly and cost-effectively. What’s more, traceability makes it possible for you to recall only the products that involve specific serial numbers, saving both time and money.

Advantage #3: Increases customer satisfaction. Another advantage of adopting traceability is stronger customer relationships. That’s certainly been the case for us, as our customers often use the information traceability provides to improve their processes, resolve issues related to defects, and help manage regulation and compliance.

Advantage #4: Improves brand management and brand integrity. Traceability is important to companies that want to protect their reputations and the reputations of their brands.

Advantage #5: Meets government and compliance mandates. Traceability helps ease the burden of and lessen the chances for fines and penalties associated with noncompliance, something that is particularly helpful in highly regulated industries such as aerospace, automotive and medical device industries.

Advantage #6: Offers a competitive advantage. Proving that products meet certain standards and/or comply with industry regulations is a competitive differentiator that traceability can deliver.

Advantage #7: Creates operational efficiencies. Implementing traceability processes helps organizations make products that are safer and of higher quality. Traceability also creates processes that can be optimized for continuous improvement. Sourcing traceable products can also save companies money –if any faults arise with a product, the OEM or subcontractor can quickly send out a recall, mitigating losses and reducing legal costs. Defects of genuine products can also be quarantined much easier than recalls of counterfeit parts.

Industry regulations and compliance

The desire for traceability information has led to the creation of independent organizations and governing bodies that have established standards and certifications that ensure traceability back to the source. The industry is responding by creating new processes for increased transparency and traceability throughout the supply chain.

Two of the top industry associations working to address and mitigate this issue are the Counterfeit Avoidance Accreditation Program (CAAP) and International Organization for Standardization (ISO).

Source: Adobe Images

Digi-Key is CAAP-certified, meaning that our counterfeit controls have been verified by an external auditing company and that our components are compliant to aerospace standard AS6496. Digi-Key also has controls for disposition, inventory, receiving and customer returns. These controls adhere to AS6496 as well.

Additionally, in March 2021, Digi-Key launched an industry-first traceability feature called Part Tracing that prints information directly on select cut tape products. This development, which is available on thousands of parts, enables engineers to better organize their components, improve traceability and reduce confusion.

In the event that suspect or confirmed counterfeit products are identified in the supply chain, Digi-Key has processes in place to quarantine the products and report the findings to suppliers, customers and the appropriate authorities.

Vertical industries also have industry groups that encourage and advocate for traceability for its members. One such group, the Automotive Industry Action Group (AIAG), was started by North America’s three largest automotive OEMs. This group requires automotive manufacturers to meet traceability standards set by the group.

Not only do these groups help prevent counterfeit activity, their standards help advance safety, quality and sustainability throughout the supply chain.

Traceability is the future

With the supply chain more digitized and connected than ever, traceability will continue to help manufacturers offer safe, authentic products. Gone are the days of listing components for sale on websites, no questions asked. Customers now demand the ability to track and trace critical components back to the OEM in case of a faulty product or a product recall.

The result is improved customer satisfaction, reduced manufacturing liabilities and, ultimately, increased revenues. While adopting traceability requires time, effort and resources, the returns companies realize far outweigh the investment. Bottom line: Complete and accurate traceability in no longer optional in electronics manufacturing; it is now a must-have.

—————————————–

Teri Ivaniszyn is vice-president, operational excellence, at Digi-Key Electronics, a high service distributor of electronic components and automation products worldwide, providing more than 11.7 million components from over 1,900 quality name-brand manufacturers.