Sheet Metal Bracket Guide

Protocase Inc.

Here at Protocase, we help you get your projects completed by manufacturing your custom enclosures, parts and panels in 2-3 days, with no minimum order. You are developing new products and technology. The faster you can get the custom parts you require, the quicker you can meet your deadlines.

One of the many parts we make on a daily basis for our 16,000 customers all over the world are custom sheet metal brackets. Whether it’s for fitting within custom enclosures, or a standalone part, we can manufacture pretty well any kind of bracket you need as long as it fits within our tooling requirements.

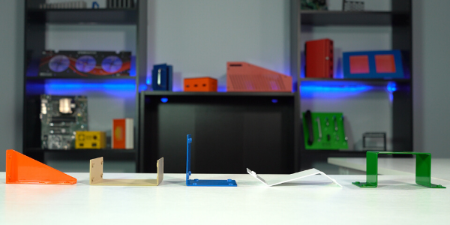

There are a number of different standard styles of brackets:

L-Bracket: This type of bracket is especially useful for when you need to mount a horizontal component to a vertical surface, or vice versa. Many of our customers also use L-Brackets to install shelves within their enclosures. One caution: Mind your material and thickness when designing these to ensure they can carry the load of whatever you are mounting.

U-Bracket: As the name suggests, this type of bracket resembles the shape of a U, and can be used for mounting two parallel surfaces together. U-Brackets also have space between the flanges which is commonly used to retain a component as it can hug both sides. U-Brackets are useful for installing components such as power supplies or hard drives.

Z-Bracket: This type of bracket is typically meant for mounting offsetting parallel surfaces. These can be useful for when you need to secure components at different heights inside of your enclosure.

Offset Brackets: This type of bracket offers a similar type of mounting style as the Z bracket in the sense that you are mounting parallel surfaces. The bottom flanges would typically mount to the inside of your enclosure, and your component or part would mount to the raised surface. These are also commonly used to retain components as well, similar to a U-Bracket.

Gusset Brackets: These typically form the shape of a triangle, and are used to provide rigidity in a design between adjacent surfaces. The name comes from a “gusset”, which is typically welded into a design to provide extra support. These can be made in any size to fit your application, and can also have their seams welded to provide even more support.

Conclusion

Our goal at Protocase is to help make your designing and sourcing of custom parts and enclosures as easy as possible. The custom brackets you require will ultimately come down to your application.

To that end, one final tip: Every bracket style covered in this guide (as well as other variations) are available as a template within our free in-house CAD software, Protocase Designer. It’s an even easier way to design, price and order the custom brackets you need for your projects.