Build a Better Rack: Best Practices for PDU Component Selection

Contributed by Carling Technologies

Racks are only as good as their power distribution units and PDUs are only as good as their components.

Carling Technologies

As densities increase and component miniaturization becomes more necessary, PDUs will also need to incorporate better circuit protection technologies. Circuit protection technologies, especially in the form of circuit breakers are the most critical element of any PDU.

Executive Summary:

Data centers are quickly evolving, thanks to initiatives that drive the adoption of green technologies, reduced physical footprints, increased densities, and better environmental controls, which in turn are changing the power-hungry monstrosities of yesteryear into islands of compute efficiency.

However, orchestrating those various technologies can be a significant challenge. A challenge that may make it easier to build the data center of tomorrow from the ground up as opposed to reengineering existing data centers into some semblance of ultra-efficiency. Naturally, many external factors will drive the decision to start new or rebuild. Regardless of the path taken, there are specific technologies that will form the foundation of an efficient data center, namely the racks that house the actual equipment and one cannot talk about racks, without talking about issues such as power distribution units (PDUs), serviceability, and environmental controls.

Equipment racks are proving to be the actual catalyst for introducing efficiency into both old and new data centers. Multiple OEMs are preconfiguring compute and storage solutions into racks, helping to increase those efficiencies and leverage high-density solutions, while also incorporating management controls, monitoring systems, and expansion capabilities. However, racks can (and do) fail, bringing operations to a screeching halt and introducing downtime into operations that are expected to function 24×7.

Simply put, OEMs need to incorporate more resiliency into their offerings and adopt best practices that can ensure that equipment functions as intended. Also, as OEMs increase equipment densities, they must also address the power and cooling needs of the racks that they choose to incorporate into their solutions. There is no denying the importance of equipment racks today, and how integrated, well-designed racks have become the foundation of a data center. Regardless of the solution housed within a rack, that rack is expected to protect the equipment contained within and also be easily serviced if the need arises.

This white paper will explore the basic premise of an equipment rack from the perspective of creating a reliable enclosure that can properly power the equipment housed within, while also removing potential power failures from the rack, yet still create an environment where efficiency and serviceability can be achieved.

Introduction:

To better understand an equipment rack’s role in the data center, one must have a good grasp of the industry terms associated with equipment housings and racks.

Data Center Rack: A physical steel and electronic framework that is designed to house servers, networking devices, cables and other computing equipment. The physical structure provides equipment placement and orchestration within a data center facility. Racks are usually prefabricated, offering slots for connecting electrical, networking and internet cables, and are built using a systematic design, and are normally classified based on the overall capacity or the number of bays. Standard racks are usually referred to as 19”, where the bays are divided into Rack Units (RU or U), where the 1RU measurement occupies 1.75” of vertical space.

Data Center Enclosure / Cabinet: Basic data center racks are normally an open framework, while a Data Center Enclosure (or Cabinet) adds sides and doors to an open rack, thus enclosing the equipment inside. Cabinets bring physical security to the equipment housed within via locking mechanisms on the cabinet doors. However, unlike open racks, cabinets must incorporate cooling methods, since airflow is blocked by the addition of panels and doors to seal the rack. Cabinets may also have more sensors, management controls, and load data gathering capabilities.

Power Distribution Unit (PDU): A rack housed electrical device that incorporates multiple sources of integrated power outputs. Each power output socket can be connected to a computing or networking device directly. A PDU is designed to manage and distribute large amounts of electricity and normally have the ability to be connected and accessed over the network or remotely and provide data and statistics on the power usage.

Circuit Breaker: Devices at the heart of a PDU and are responsible for protecting IT equipment from damage due to power spikes or other abnormal occurrences. Breakers are often incorporated into transformers and offer the ability to collect data and measure power usage, as well as loads. Breakers are the most important safety device in a PDU and can be configured to bring additional protection to equipment.

Internet of Things (IoT): An ever-growing network of physical objects that feature an IP address for internet connectivity, and the communication that occurs between these objects and other internet-enabled devices and systems. IoT devices can include sensors, controllers, security systems, thermostats, appliances, and other devices, which utilize embedded technology to communicate via TCP/IP protocols.

PDUs have been a fundamental part of data center power distribution architecture for decades and are facing the same evolutionary demands placed upon the reengineering of data centers to introduce increased reliability, improved efficiencies, and increased densities. That means PDUs themselves have to become more efficient, more reliable, and take up less space while generating less heat. What’s more, PDUs have to incorporate technologies that support remote monitoring, remote management, and data collection capabilities that can be analyzed to detect potential failures, or shifting loads that may indicate other problems.

As densities increase and component miniaturization becomes more necessary, PDUs will also need to incorporate better circuit protection technologies. Circuit protection technologies, especially in the form of circuit breakers are the most critical element of any PDU. Selecting inferior circuit breakers can lead to equipment damage, unreliability, and even dangerous situations, such as fires. As IT equipment advances, it may become more susceptible to power spikes, voltage drops, harmonics, and other electrical factors that can cause damage. It is critical for OEMs offering data center racks to consider the implications of “dirty” power on the equipment housed within the rack. Otherwise, warranty claims, service calls, and other SLA derived services may increase, reducing the reliability of deployed systems and potentially damaging customer relationships, while also damaging reputations. While an enclosure is a physical system within itself, it must be designed to deal with the physical equipment housed inside, and that means incorporating PDUs and circuitry protection that extends the life of the equipment.

Although PDUs have been used in data centers for decades, PDU designs and manufacturing must adapt to needs of state-of-the-art data centers. PDU suppliers that focus on engineering and production, while also having the capabilities to optimize their PDUs’ performance will prove to be the choice for incorporating into data center racks that will meet future needs as data centers continue to evolve.

Section I: The Symbiotic Relationship of PDUs and Circuit Protection

In their most basic form, PDUs do much the same job as a power strip; the PDU gets current from a single source, and then offers multiple connections that can power multiple devices, such as computers, peripherals, and networking gear. PDUs are usually incorporated into equipment racks and are designed to power rack-mounted equipment, such as servers, switches, routers, appliances, and cooling fans. PDUs are found in data centers, network closets, phone systems, and other business or industrial environments where racked equipment is used.

Beyond power distribution, PDUs also can offer monitoring and management features, as well as component serviceability. PDUs can also support metered, monitored, switched, and other connections, based upon the needs of the equipment in the rack. Many PDUs come in 1U or 2U form factors and can be added to racks and enclosures as needed. Some PDUs are designed to be further integrated into an enclosure and may support hot-swappable circuit breakers or other capabilities beyond what a basic PDU offers.

From the outset, PDUs are designed to offer some form of circuit protection and offer different options for circuit control and protection. PDUs can incorporate basic protection in the form of a simple circuit breaker, other PDUs offer metered type connections, where amp loads are metered to prevent overloads. Other PDU types include monitored or switched, where an SNMP interface is offered for management, while switched supports remote control of individual outlets on the PDU. Of course, there are other combinations that incorporate multiple features, such as auto-transfer capabilities, combined with monitoring and metering. Picking a PDU for specific needs means looking at the options available and determining what makes the most sense for the equipment housed in the rack.

PDUs are also in the middle of a battle over currents, specifically AC or DC. AC has been the leading primary power source for data centers, however much of the equipment actually runs on DC, meaning that AC has to be converted to DC inside the device itself, creating waste. A study by the shows on average, DC improved efficiency about 15.3 percent over AC systems at a data center operated by Duke Power in Charlotte, North Carolina. What’s more, interest in DC is growing because of alternate energy technologies, such as solar and wind. Currently, those technologies generate DC power, which is then converted to AC power to be fed into the primary power lines, and then converted back to DC at the device level. Ultimately, keeping everything in a data center on DC power can save at least three energy-wasting conversions; at the UPS, at the PDU, and at the power supply unit (PSU) on servers or networking equipment.

Electric Power Research Institute

Although PDUs can support many different types of circuit protection, support AC or DC environments, and even incorporate advanced monitoring capabilities, while also working with different power feeds, one primary issue should still be considered when choosing a PDU — quality. PDUs are critical in the data center, and a failure of a PDU can bring a complete rack of equipment down, or even worse, damage that equipment. That is where both quality and serviceability come into play. Those selecting PDUs need to consider how the PDUs are designed and built, what materials are used for the sockets, connections, and mounting elements. The functional temperature ranges, measured MTBF, and warranty support. Serviceability elements, such as hot swap breakers, ease of access to replacement parts, monitoring, and the ability to perform preventative maintenance should also be considered. The simple fact of the matter is that enclosures can outlast the housed equipment, in other words, new devices such as servers or switches may be installed over time, replacing other devices. The cabinet itself may not be changed, meaning that the PDUs chosen should offer a much longer life than typical data center equipment.

Section II: What to Look for in Circuit Protection

Selecting circuit protection components can be a complex task, there are many factors to consider when making that choice. For the most part, PDUs are all about circuit protection, and that means circuit breakers play a critical role. After all, PDUs are expected to stop surges and prevent overloads.

PDUs can also be designed to control current per outlet or measure spikes or even the quality of the power provided. In other words, PDUs can be complex pieces of equipment that are expected to protect other complex pieces of equipment, all stored within a challenging environment. Making sure equipment is properly protected means selecting a PDU that can operate under the expected conditions. Important criteria to look at includes:

Operational Environment: What are the temperature ranges the PDU is likely to encounter, what levels of humidity are expected. Better components have the ability to work under greater variations in temperature and humidity.

Ease of Service: Can the PDU be reset? Does it support hot swaps of components? Does it provide a bypass capability, are replacement parts readily available? How long is the product life cycle? What guarantees are in place to ensure long-term parts availability?

Reliability: Has MTBF been tested? What is the rated number of cycles on the components? How does the device deal with dirty power sources, load ramping, surges, and other power problems?

Safety: What type of circuit protection is in use? Are buttons and controls protected from accidental activation? Is there any method to prevent accidental disconnects? How are cables routed? Are there any sharp edges? Is there ground fault protection? How well is the PDU secured to the rack?

Efficiency: Are increased densities supported (1RU sizing)? What footprint reduction options are available? Are management and monitoring tools included? Are any types of power alarms available? Are hydraulicmagnetic circuit breakers available?

Other features to consider include visual representation of PDU status, either by LEDs or clearly marked switches and panels. Being able to determine the power status of an enclosure at a glance is important in large data centers, where staff has to quickly locate potential equipment problems.

Nevertheless, protecting connected devices comes down to one undeniable fact, and that is the quality and type of circuit breaker involved. Circuit breakers are the most critical component of any PDU. Much like any other technology, circuit breakers have evolved and offer many different ancillary features that mark design excellence. As IT equipment has become more sensitive to power variances, surges, and so forth, circuit breakers must be up to the task and properly integrated into a PDU.

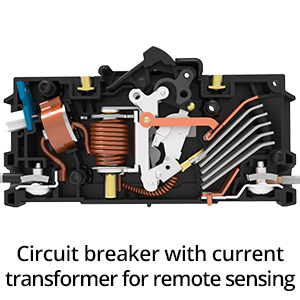

In some cases, that may mean selecting circuit breakers that are compact in nature and designed to operate in confined spaces. Those breakers should use hydraulic-magnetic circuit protection and when transformer enabled, be able to sense current down to a level of 1%. That enables precise current monitoring and reporting required for back billing of the actual power consumed by data center storage and routing devices, while also facilitates load adjustments and maximum efficiency.

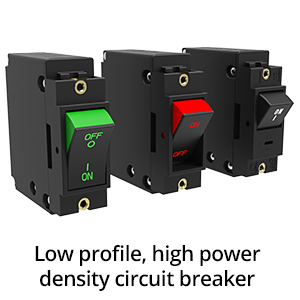

In other cases, circuit breakers that are designed for high power density situations may be required. Those breakers should come in low profile form factors, use hydraulic-magnetic actuator mechanisms and support customizable trip delays, such as Instantaneous, Ultra Short, Short, Medium, Long, Short Hi-Inrush, Medium Hi-Inrush, and Long Hi-Inrush.

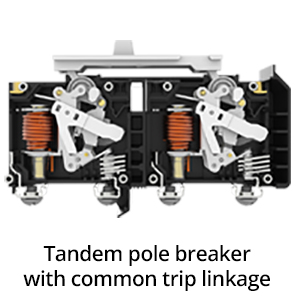

Depending on the intended application of a PDU, circuit breaker designs may have a dramatic impact on the suitability of that PDU. Take for example cases where it is critical to prevent manual override of a breaker in an overcurrent situation. That may mean using a tandem pole circuit breaker, which is designed with a common trip linkage ensuring if one pole trips, the tandem pole simultaneously trips. It’s also important that the breaker incorporates a trip-free mechanism, which is a safety feature making it impossible to manually hold the contacts closed during overcurrent or fault conditions.

Of course, PDUs designed for DC environments require adequate circuit protection as well. DC powered systems have different needs and normally incorporate high DC voltages (up to 600VDC), along with high amperages. Better circuit breakers for those environments employ hydraulicmagnetic mechanisms, along with permanent magnets that can create strong magnetic fields that are used by arc runners to better react to spikes and help to cool the breaker as well. Those breakers should also support multiple trip delays, with DC instantaneous being a critical starting point. Other available delays should include Ultra-Short, Short, Medium, and Long DC Switch only.

Section III: The Path to Customizable PDUs

There is no doubt that data centers are evolving, both in what is expected from a service perspective and the physical organization of the equipment housed. Much of that change has been driven by a quest for efficiency and the introduction of new technologies. Take for example the rise of IoT, where all sorts of devices are being deployed in the data center and across the enterprise. Those devices include sensors, security systems, controllers and many other pieces of equipment and all share internet connectivity in common.

In many cases, data centers are becoming a conglomeration of IoT devices, and equipment racks may fall under that classification as time goes on. IoT for the most part gathers data in real-time and reports to analytics platforms for analysis to enhance decision making or trigger alerts based upon trends. As the impact of IoT grows, PDUs will most likely become part of the industrial IoT ecosystem, reporting on elements such as power usage, heat, status, and other elements. PDUs, if properly equipped, can become part of the industrial IoT ecosystem and help data centers better understand power usage, especially in multi-tenant environments or co-locations.

The concepts of IoT fit squarely into active management of PDUs, where capabilities such as out-ofband and in-band monitoring are becoming critical tools. In-band monitoring provides the realtime ability to understand what exactly is occurring with a PDU. Issues such as load, power quality, temperature, and other derived information can be reported in an active fashion to a management console. Out-of-band monitoring introduces the capability of diagnosing a component that may not be functioning, or sending commands to a device that may be down. Both of those capabilities lend themselves well to management of large data centers, where PDUs have the potential to become part of a managed infrastructure.

Adding those capabilities to PDUs means that PDUs must have the potential to be customized and integrated into other systems. That is something that can usually be achieved with APIs or other software methods to integrate PDUs into other management systems. A whole ecosystem of ITSM (I.T. System Management) solutions exist on the market that support integration via APIs. Here, those adopting PDUs that offer APIs, can create integration packages that support popular ITSM platforms, bringing additional value to the data center racks and enclosures that are being offered.

Customization capabilities also fit well into the realm of big data, business intelligence (BI), and automation systems, such as RPA (Robotic Process Automation). The ability to feed data to those systems gives operators the ability to derive insights from trends and supports the ideology of relational data analysis from multiple sources. Automation technologies can be used to control PDUs or related power systems based upon policies derived from insights. Machine learning can further enrich the data by discovering outliers and exceptions that could bring predictive analytics to bear. An important consideration for data centers that are dealing with issues of scale.

The ability to scale on demand has become a critical capability for service providers operating data centers. Scaling up often means spinning up additional compute resources, while scaling down means shutting down underutilized resources. PDUs that can control power to individual servers or devices in a rack may have the potential to make scaling a very efficient process, by eliminated waste and shutting down power to inactive machines, while also participating in the power-up phase of increasing scale.

PDUs have the potential to become an important part of the adaptable data center, where intelligence is used to identify needs and then take part in boosting efficiencies. By comparing server utilization against power consumption, it is possible for PDUs to become part of the solution needed to maximize compute utilization by shifting loads to active servers and shutting down underutilized systems. The key to accomplishing the outlined goals can be found in the form of customization, where the PDU vendor can offer the services and support to make such things possible via APIs, custom programming, or pre-integrated capabilities.

Section IV: Call to Action

Implementing the best technology starts with identifying that technology. While there are some clear-cut best practices on how to identify the best technology, there are some less tangible examples that further outline the search for excellence:

Seek Value: Always remember to consider the value offered by a PDU. Although value may be somewhat of a judgement call, there are indicators that go beyond initial price. Examples include support, feature set, warranty, customization, availability, and of course, the relationship with the vendor.

Validate Protection: One of the most important capabilities of a PDU is its ability to protect equipment from damage. That means the PDU should incorporate circuit protection technology, such as circuit breakers, that are specifically designed to exceed the requirements of the target environment and incorporate safety features and customizable options to meet the criteria of the equipment to be protected.

Look to the Future: PDUs that fit the bill today may not meet the requirements of tomorrow. It is critical to work with vendors that can provide some form of future proofing their offerings. In other words, the ability to upgrade components, add new features, and have long term access to replacement parts all fit well into the concept of future proofing.

Seek Design Excellence: Design is a critical element of a good PDU. The devices should embrace intelligent design and address common issues, such as ease of service, protected switches, indicators, integration capabilities, hot swappable components, and better circuit protection.

Seek Additional Opportunities: The ability to maintain a long-term relationship with a customer is tantamount to achieving ongoing revenue. Look for opportunities to build services around PDUs and racks, ranging from monitoring to proactive maintenance, to outsourced management of data center equipment, or even the execution of service contracts and SLAs. PDUs offer a path to building long-term relationships with customers and creating managed services that can ease burdens on the customer, yet provide long-term service revenue. l

Download White paper

Fill out the form below to download this white paper.