Understanding the 3rd edition medical safety standard and using dc-dc converters to provide isolation

By Ann-Marie Bayliss, product manager, Murata Power Solution

Power Supply / Management MedicalAny electrical medical appliance, healthcare or dental product must comply with specific country or industry safety standards that are based on IEC60601-1. Now in its third edition, the standard includes the general requirements for the provision of basic safety and essential performance for any dc-dc and ac-dc component power supplies in the equipment. Regional certification authorities, such as the European Union, where the initial compliance date for the 3rd edition was June 2012, have adopted the standard. As part of the European Union Medical Device Directive the end equipment must also have a risk analysis management package provided as per the requirements of ISO 14971. However, the IECEE Medical Electrical Equipment Task Force issued a technical decision that component ac-dc and dc-dc power supplies are not subject to the requirements of risk management.

The scope of IEC60601-1 3rd edition covers more than that of isolation for electrical safety. The operating environment, location that the end-product will be used in, the potential for presence of contaminants such as conductive or non-conductive pollution and likelihood of moisture ingress are all factors that need to be considered in the design of the power supply and the overall end-product. Other critical parameters including the mechanical strength of the enclosure, accessibility to hazardous voltages, temperatures and access to mechanical hazards is also highlighted by the standard.

In the context of medical applications the overall aim of a safety standard is to protect users of equipment such as vital signs monitors, drug dispensing equipment and dialysis machines from potential hazards, and most importantly electric shock. This also relates to operators or patients who might touch or have sensors directly connected to them. The 3rd edition standard stipulates two categories of protection, each with their own requirements. These are ‘Means of Operator Protection’ (MOOP) and ‘Means of Patient Protection’ (MOPP).

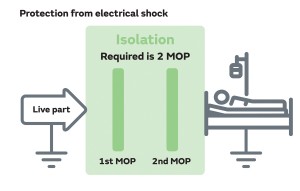

For both MOOP and MOPP the key requirement is reducing the risk of any unintended electrical current from passing through the human body. The need for electrical isolation is vital in order to prevent this happening in the form of physical spacing and/or insulating material. With hazardous voltages present in a system a robust and reliable approach to isolation is needed such that multiple and un-related insulation system failures would need to occur before an operator or patient is put at risk. To achieve this, two independent measures of protection (MOOPs or MOPPs as appropriate) are required or a single measure of physical isolation such as creepage/clearance or solid insulation deemed equivalent. Previous iterations of IEC60601, a power supply for example that meets the 2nd edition requirements for reinforced isolation is likely to comply with the 3rd edition for 2 x MOOPs. However for patient protection (2 x MOPPs) the requirements are more stringent. Notably the creepage and clearance distances need to be greater as does the thickness of the insulation used. (Creepage is defined as the shortest distance along the surface of the insulating material between two conductive parts. Clearance is the shortest distance through air between two conductive parts). Also for patient protection, there is a higher dielectric high potential (HiPot) test value and leakage currents need to be a lot less.

Design to achieve the required category of insulation/isolation will vary depending on a number of factors. These will include the operating system voltage (i.e. the mains supply), the overvoltage category of the system, and the material group type for creepage surfaces, pollution degree category and operating altitude. Altitude is often neglected but must be considered with a correction factor applied to clearance distances. For example equipment that could be operated in Quito, the capital of Ecuador at 2850 m altitude should increase clearance distances for operator protection by 15%.

Figure 1 illustrates the basic concept of providing isolation from electrical shock between a live part and a patient with two means of protection. The exact methods of the protection can differ and can be a combination of physical distance, solid insulation or multiple layers of thin insulation. For example, for patient protection in 250Vrms systems, the isolation could be 8 mm physical separation across one barrier or two barriers each with 4 mm separation. 1 MOOP, 2 MOOP, 1 MOPP and 2 MOPP.A practical example would be where the first measure of protection is provided by an IT-grade ac-dc converter meeting the requirements of IEC60950 for reinforced isolation followed by a dc-dc converter meeting ‘basic’ or 1 x MOPP requirements for IEC60601, the combination being equivalent to a 2 x MOPPs insulation system. The reason is that the ac-dc converter that meets IEC60950-1 Reinforced Insulation would meet the IEC60601-1 requirements of 2 MOOP or 1 MOPP. Note however that other factors such as fusing and overall leakage current need to be considered for full patient protection compliance.

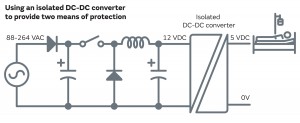

In some applications, isolated dc-dc converters be to provide two means of protection. Figure 2 illustrates a mains powered circuit generating an intermediate non-isolated 12V which is passed through an isolated dc-dc converter to produce 5V. The dc-dc is powered from a seemingly ‘safe’ 12V but with a direct connection to high voltage ac so the converter must have two means of protection for the 5V to be deemed safe.

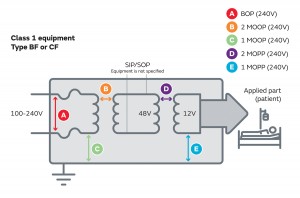

Another example where a dc-dc converter may need to have a defined level of insulation is shown in Figure 3. Here full patient protection against mains voltage is provided by the ac-dc converter under normal conditions (barrier B). However, the dc-dc converter, 1 MOPP barrier E, is providing protection from current flowing through the patient back through the dc-dc to ground from other faulty equipment energising the patient. If there are unspecified input and output lines connected to the equipment (shown as SIP/SOP in the diagram), the dc-dc must have 2 MOPP. If the SIP/SOP lines are specified with a minimum of 1 MOPP, the dc-dc only requires 1 MOPP.

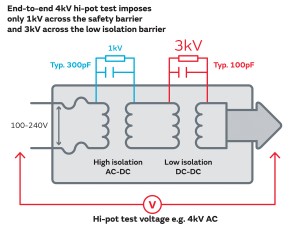

Sometimes a high level of dc-dc converter isolation provides a convenience in product testing. Figure 4 shows a typical application where a low isolation rating dc-dc with low capacitance and high insulation resistance follows a full safety rated ac-dc supply. If an end-to-end hi-pot test is performed, most of the test voltage drops across the dc-dc by a simple pot-down effect perhaps way above its rating. If it happens not to fail, the main safety barrier in the ac-dc has not been verified. If the dc-dc is anyway fully safety rated this at least leaves the confidence level in the equipment high.

When selecting power converters in medical and other safety rated applications, the ‘working voltage’ must be specified. For ac-dc converters this is normally the ac mains input. For dc-dc converters, the working voltage can vary depending on the application. For example the Murata MEJ1 series is rated for 1 MOOP at 200Vrms up to a maximum ambient of 85C while the Murata NCM6 series is rated for 2 MOOPs at 250Vrms. These are combinations that the manufacturer has elected to have agency tested. The same products can qualify for different ratings for example the MEJ1 series could be rated for 2 MOOPs but at lower working voltages. The manufacturer will be able to advise what combinations are possible.