Selecting the optimal thermal management technology

By Adam Wells, Pfannenberg

Electronics Thermal management enclosures enclosures thermal management Thermal managementHow to choose a cooling unit that protects electronics in a specific application

The use of cooling technology is ubiquitous across industry, yet choosing the correct technology for a specific application can prove a challenge. Each choice depends on a variety of factors and the wrong choice could lead to tremendous losses for a business.

Air-to-air heat exchangers can offer an efficient solution in harsh conditions.

As thermal management technology options proliferate, choosing the correct cooling product can ensure continuous operation at low cost by protecting critical electronic systems. An incorrect choice could be disastrous, resulting in decreased productivity and efficiency, increased maintenance frequency and even compromised safety. In order to avoid these costly mistakes, facilities engineers should evaluate both cooling requirements and ambient circumstances before selecting a technology. These include heat load, the ambient temperature range, the presence of particulates or debris, enclosure location and material, and various other specifications. This brief guide will equip engineers with a basic framework to determine the best thermal management option for an application.

Higher enclosure temperature than ambient temperature

In the majority of applications, a standard filter fan matches requirements. As far as thermal management goes, these are the baseline product for most enclosure and electronics cooling.

Filter fans simply utilize pressure differentials to displace warm air in an enclosure with cooler, ambient air from outside. These products are affordable, effective, and can be utilized in multiple contexts to meet specific business needs.

As useful as they are, filter fans rely on outside air that is both clean and non-hazardous, and some cases in which ambient air is cooler than the target enclosure temperature require protection from the elements. In food preparation plants where particulates fill the air, in factories where airborne chemicals would corrode electrical components, and in other cases for which total separation between the cooled enclosure and the outside air is required, the ideal solution is an air-to-air heat exchanger. While still offering the cost efficiencies that come with using ambient air, an air-to-air exchanger offers a variety of cooling capacities while ensuring total separation of enclosure and ambient air. Applications include indoor-temperature-controlled environments, common in IT sector and food and beverage applications.

Higher ambient temperature than enclosure temperature

Both filter fans and air-to-air heat exchangers are only viable, however, if the temperature inside the enclosure should be higher than in the ambient environment. Otherwise, alternate cooling technologies will offer a better solution.

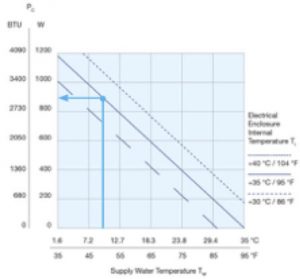

The performance of an air-to-water heat exchanger depends on the difference in the water temperature and enclosure air temperature.

The primary alternative is a closed loop cooling unit. These units actively pump out heat from the enclosure while simultaneously cooling the air with an evaporator. This process, when coupled with a dehumidifier, allows closed loop cooling units to operate without relying on a cooler ambient temperature. Like air-to-air exchangers, the enclosure is completely separated from the ambient air.

With extremely hot or dirty outside conditions, however, a closed loop cooling unit may not suffice. In these circumstances, chillers and air-to-water heat exchangers offer preferable methods of heat removal. A chiller is used for cooling needs that involve high or fluctuating heat-loads, precise temperature controls, or the need for flexibility in the location of the cooling unit. The food and beverage industry, for example, often utilizes these technologies to fit their specific cooling requirements. Chillers operate like basic refrigerators and can be modified based on coolant type, heat-load needs, or environment type. Alternatively, an air-to-water heat exchanger transfers heat into an on-site water source. This allows for cooling without any heat being transferred into the ambient environment. If a water source is not available on site, a cooling solution involving a system made of both chiller and air to water exchanger is often installed.

Thermal management expertise can save costs

Although these are the basic rules of thumb for proper thermal management, considerations must be made for sizing and wattage requirements, along with any other factors that may result in an exception to these guidelines. Recall that a wrong choice in cooling technology can prove costly: productivity, energy efficiency, equipment longevity, maintenance, safety, and overall cost all could be affected.

The right advice can result in a major improvement in operations. For one large plastics manufacturer, plastic dust in the air constantly coated the heat-exchanging coil inside the factory AC units, causing them to fail. Pfannenberg suggested an enclosed system to fix the problem in the form of a combined chiller and air-to-water exchanger, ultimately saving the manufacturer thousands of dollars in downtime and maintenance. The selection process is complicated, and utilizing the expertise of application engineers is often the most efficient way to ensure the proper selection of a cooling system.

The need for proper cooling technology provides a first line of defense against the degradation of critical electronics, facilitating innovation in the new digital economy. To fully capitalize on the latest thermal management technologies, businesses must prudently consider all variables and conditions during the selection process.