Reaping the benefits of the connected factory

EP&T Magazine

Electronics Contract Manufacturing Engineering IoT CEM contract manufacturing Editor Pick Electronics EMS facility factory IIoT Industry 4.0 Manufacturing plant services softwareIndustry 4.0 revolutionizes the manufacturing process by bridging the gap between high-level IT and floor-level Operational Technology

There’s been a lot of talk lately about how Industry 4.0 is changing manufacturing. And rightly so. It is the fourth major industrial revolution in history – and it is underway. Industry 4.0 revolutionizes the manufacturing process by bridging the gap between high-level Information Technology (IT) and floor-level Operational Technology (OT), leveraging intelligent data insights to power factory-wide communications.

To be successful, Industry 4.0 must be embraced as a long-term, strategic mindset of digital transformation that dynamically alters a manufacturer’s entire operational perspective. It is what Dorigo Systems, a Canadian electronics manufacturing services company, committed to when plans for their new facility were being made back in 2018. Not only did they want to build a new manufacturing space that would be flexible to meet their future growth, but also design an infrastructure that would bring new levels of productivity.

Dorigo Systems Ltd. new facility in Burnaby BC.

What was paramount to Dorigo Systems was their commitment to providing their customers with a seamless and transparent manufacturing experience from Request for Quote to Final Delivery. The combination of their state-of-the-art facility, supported by Industry 4.0 connected communications, would significantly boost productivity, reduce costs and improve product quality services. What they discovered, is that the way forward with Industry 4.0 is not an end point – it is a journey – and one shared with their strategic partner, Aegis Software and their FactoryLogix Manufacturing Execution System (MES).

“Factories with Industry 4.0 capabilities can shift their operations on a dime, flexibly adapting to meet changing customer demands, enhance productivity, reduce waste, and accelerate production,” says Deb Geiger, VP global marketing of Aegis. “Production plants can maintain closer contact with customers and supply chain partners and achieve an agile, flexible model for mass customization.”

Industry 4.0 is automatically controlling materials flow to eliminate downtime and operate at the lowest level of inventory possible. The ultimate goal is to transform manufacturing into an environment that is adaptive and customer-centric.

“Working with us is like having your own state-of-the-art production facility without the overhead, manpower or production headaches,” says Alex Chassels, VP operations, Dorigo Systems. “The Aegis platform, FactoryLogix, allows us to check on production at every step in the manufacturing process, continually improving our quality and ongoing on-time delivery for every product we build while simultaneously eliminating waste in the process.”

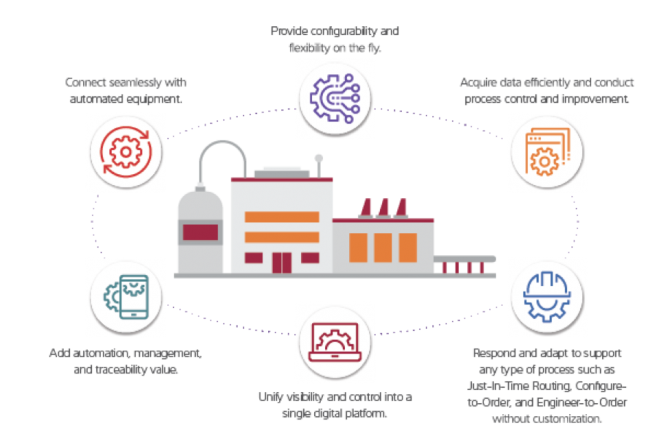

Empowering Unparalleled Advancements in Smart, Connected Manufacturing

A connected factory ecosystem is driven primarily by a unified view of the enterprises’ strategies and operations. With enhanced visibility and real-time data sharing, Dorigo’s connected Industry 4.0 ecosystem creates a two-way system of information sharing that ensures operations adhere to factory requirements and accurate operating protocols.

“We have the ability to communicate and display complex processes in a simplified format,” says Adriana Baciu, product engineering manager, Dorigo Systems. “With Aegis’ FactoryLogix platform, we are able to have the agility and traceability to seamlessly connect our engineers with the manufacturing floor. FactoryLogix adapts to Dorigo’s electronics manufacturing processes.”

Through intuitive interfaces, contextual awareness, interactive work instructions, voice and gesture capabilities, and dynamic alerts—all powered and enhanced by AEGIS’ data-sharing—Dorigo Systems can train employees more easily while also improving employee satisfaction and the overall experience.

“Our engineers are able to make anything we want – when we want it,” says Baciu. “We can automate-to-order as the system dynamically adapts to our needs. FactoryLogix separates the process from the machine so you can export a manufacturing process where you need it. By using Just-In-Time reroutes we can quickly readapt to the customer change requests during New Product Introduction projects without loss of traceability or control. We use the platform to design and standardize our work centres.”

Source: Aegis Software

Aegis’ FactoryLogix software integrates high-level Enterprise Resource Planning (ERP) with the production operations via MES and its Industrial Internet of Things (IIoT) framework, creating a two-way system of information sharing that ensures operations adhere to factory requirements and accurate operational information is used to plan future projects.

“Industry 4.0 introduces tools that improve productivity, make everything visible and available for analysis, and ensure that operations remain proactive as opposed to reactive,” says Jason Spera, CEO and co-founder, Aegis Software. “Embracing digital transformation, however, does not occur overnight. A typical framework for digital transformation and Industry 4.0 manufacturing technologies begins strategically, and then works its way down to development and implementation. Dorigo Systems is a great example of how this can be achieved over time.”

Quality Standards at Your Fingertips

“In real-time, we know who and how long a team member is working on a product along with the tools they are using,” states Adriana Baciu. “Engineers know if materials and equipment are up to the necessary standards to be used for specific products using the FactoryLogix interface.”

For example, if a material station is set up, it will be checked to ensure it is not using an obsolete program or expired materials. FactoryLogix does this automatically and reports back to Dorigo’s engineering team providing dashboard summaries.

“We can also control the training of operators by ensuring they are certified to operate a specific machine or if they require retraining,” says Baciu.

What the team at Dorigo Systems has experienced using Aegis is that quality standards are at their fingertips. The system provides tight control and traceability. Dorigo Systems uses Factory Logix to control, monitor and implement quality throughout the organization.

“The system so beautifully integrates all of the necessary functionality to easily standardize work instructions templates, operator interface template and quality plans and processes,” says Baciu. “Onboarding of new projects is expedited.”

MES empowers operators to leverage specialized manufacturing insight without taking excessive time for cross-training, quickly establishing a high level of team-wide flexibility.

“The software is guiding us to do the right thing,”Baciu states, “and uses the best practices and principles for manufacturing.”

Industry 4.0 requires making sense of new IIoT analytics. It is why relying on an expert technology partner is so critical to Dorigo’s ongoing success.

Aegis’ FactoryLogix platform gets more robust by activating new modules. “We love the FactoryLogix xLink IIoT machine and device adapters that transmit data from various factory resources into the FactoryLogix system,” says Baciu. “We no longer have to manually manage data and we always know where products are in the factory and their status at every stage of manufacturing.”

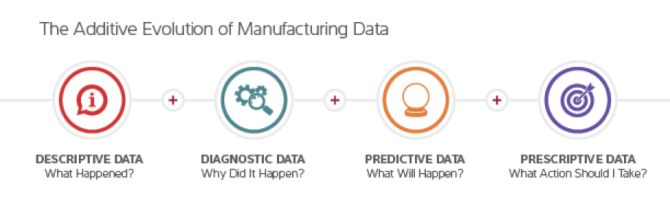

By implementing Industry 4.0 Big Data, Machine Learning, and AI techniques, Dorigo Systems can do much more than recognize key trends. “We are able to optimize and simulate operational excellence, power new perspectives for statistical process control and business management, set objectives that deliver real value while being more predictive and prescriptive into the status of our operations,” states Chassels.

Source: Aegis Software

The Future of Manufacturing

Aegis’ FactoryLogix combines system consolidation with seamless integration to simplify and streamline processes. Its integrated platform of adaptable, state-of-the-art software modules support any form of discrete manufacturing without customization, providing Dorigo Systems with tools to improve every aspect of their operations and enable Industry 4.0 benefits.

From production and logistics to analytics and integration, FactoryLogix MES powers the essential components of Industry 4.0—innovative adaptability, intelligent insights, a connected ecosystem, configurable processes, and complex simplicity—shifting centralized, disconnected production to decentralized, customer-centric models.

“Our strategic partnership with Aegis Software is providing the foundation which supports a dynamic and diversified future for Dorigo Systems,” says Alex Chassels. “We are empowered to take advantage of unparalleled advancements in smart, connected electronics manufacturing which supports our Seamless Customer Experience that brings the most innovative products to market.”