COVID-19 will force 5 years of manufacturing innovation into the next 18-months

By Anna-Katrina Shedletsky, CEO and founder of Instrumental Inc.

Manufacturers will seek solutions that leverage the power of the Cloud for visibility and automation that optimizes work, necessity will drive invention

The environment in which electronics manufacturers are building has changed rapidly in the last couple of months. As under-resourced teams face the challenge of solving COVID-19 problems, they’ll need technology that gets to the very root of these issues: solving for distance. Between solutions that leverage the power of the cloud for visibility and automation that optimizes work, necessity will drive invention: manufacturers will do five years of innovation in the next 18-months.

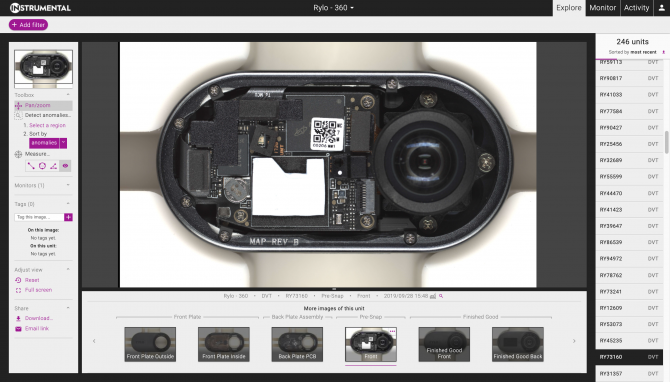

As COVID-19 forces electronics companies to change their manufacturing strategies, solutions like Instrumental are in increasing demand for their ability to enable remote work during development and production. Instrumental’s software, depicted above, provides engineers with eyes into the factory via product images that get processed with AI to surface defects.}

Aggregating data

Cloud databases are uniquely suited to help manufacturers aggregate data across multiple on-premises systems, something that enables reduced travel and distance during COVID-19. To date, the manufacturing industry has lagged behind in the adoption of cloud technologies – favoring on-premises solutions as the ‘safer’ place for sensitive manufacturing information. Despite lingering unfounded security concerns, the benefits of the cloud have become too good to ignore and even before COVID-19 mindsets had started to shift. By aggregating their data in the cloud, companies get real-time data for remote oversight, aggregated and comparative intelligence across global factories, suppliers, and business units, and the ability to leverage technologies to solve pressing problems.

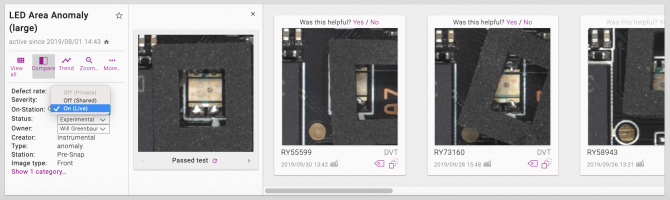

Adoption of cloud data unlocks technologies like AI, which is especially helpful considering the massive amounts of data that needs to be processed in order to make remote work productive in manufacturing. Instrumental, a manufacturing optimization platform that leverages AI to help electronics companies catch defects in development and production, creates remote work benefits with the cloud. The firm’s instrumentation captures images as units get assembled and leverages the cloud to make them available in real-time to globally distributed teams.

“Adoption of cloud data will unlock remote oversight, remote work and optimization”

This visual data record enables engineers to use Instrumental’s AI to surface unanticipated defects in minutes during development and catch quality shifts in real-time during production without stepping foot in the factory. AI tests can also be pushed to the line from anywhere using the cloud, which means teams can continually improve quality and core metrics like rework and scrap costs from home. Implementing cloud data and leveraging AI solutions that have ROI should be a top priority for both manufacturers and the brands that build at them. In the short term this data enables some level of oversight and normalcy in a world where engineers cannot travel, and in the long term it will pay dividends for manufacturing optimization of products and processes.

Instrumental enables teams to detect manufacturing defects with AI from anywhere in the world. Source: Instrumental Inc.

Automation has an unprecedented opportunity

Electronics manufacturing is a highly manual process. Hundreds of pairs of hands touch phones and laptops during assembly. These products are developed, ramped, and run over months, not years – investment in automation for products with such short cycles doesn’t pay off. Line space is at a premium, so before COVID human operators were placed at 0.6m intervals – that spacing will need to be significantly increased in order to meet guidelines to reduce virus transmission. Couple the spacing issues with PPE requirements, and the increased cost to keep human assembly safe creates an unprecedented opportunity for stronger returns on investment for automation.

While manufacturers may initially be hesitant to take on large capital intensive projects like automation right now, the payoffs of a workforce that doesn’t take breaks and doesn’t get sick will be appealing to those with strong capital positions – enabling acceleration in efficiency during this time that will cut costs and boost bottom lines.

Necessity will drive adoption first, then more innovation

If you talk to folks in the manufacturing industry, you’ll find that many have been burned by falling for the promises of buzzwords over the past decade. This has left a general aura of suspicion around new technologies for leveling up – though technology investment in manufacturing remains high when there is a pressing need.

Today’s need is great – manufacturers will be looking for solutions that directly solve their pain points, can be implemented quickly (days and weeks, not months), and have the potential for long-term, post-COVID-19 impact. Solution providers are adapting and many are ready to meet this demand.

COVID-19 requires the modernization of manufacturing. Since the problem of ‘distance’ can’t be solved without the adoption of technology, we’re going to see many years’ worth of innovation in the next 18 months. Many of these solutions will bring greater efficiency, lower costs, and less waste, enabling them to outlast the pandemic and pay for themselves quickly.

———————-

Anna-Katrina Shedletsky, CEO & founder, Instrumental Inc.

Instrumental Inc. provides a manufacturing optimization platform that helps accelerate product maturity, de-risk ramp and improve yields for CEMs. https://www.instrumental.com/