Making automation work with legacy systems

By Rich Miron, Digi-Key Electronics Corp.

Automation / Robotics Electronics Engineering Supply Chain automation automationSmart manufacturing, or Industry 4.0 (the fourth industrial revolution) which is empowered by the Industrial Internet of things (IIoT), can enable companies to improve key performance indicators like productivity, equipment uptime and product quality. It does this by combining automation with big data to not only improve productivity, but to also reduce waste, lower energy consumption, and enhance factory flexibility.

Companies may be eager to take advantage of the opportunities that are available, but uncertain about how to make the change without incurring unacceptable disruption or wasting their investment in existing equipment.

Businesses have several considerations which may present additional hindrances to transitioning their production lines including the significant capital commitment in machinery currently in place and the fact that owners may not be ready to engage in wholesale replacement, or an upgrade project that may involve reprogramming controllers such as PLCs. PLC programs can be complex, and even if enough is known about the current program for successful modification to be possible, the PLC itself may not have enough additional resources available to support the extra functionality.

Adding smart to existing facilities

To address these concerns, some organizations are exploring approaches to introducing web connectivity as an add-on to an existing installation. This opportunity may help to lower the cost of entry to smart manufacturing, especially in cases where the installed equipment may contain large numbers of sensors that are used for basic process control. Although rich data may be currently collected, the lack of external connectivity prevents the company from realizing its full value.

The Industrial Internet Consortium (IIC) has published the Smart Manufacturing Connectivity Testbed, which proposes a solution for extracting data that normally flows through an I/O module to the PLC. This testbed replaces conventional I/O modules with a gateway that sends the data to an IT system through an additional communication channel using the industry-standard OPC Unified Architecture protocol. By using open standards for communication and a common device model, the IIC proposal enables users to configure and manipulate the sensors via the IT system.

Connect to a machine, connect to the Internet

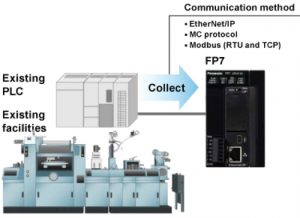

The Panasonic FP7 dual-role PLC has been designed to enable companies to introduce IoT functionality as an add-on to an existing automation system. The controller is equipped to deal with any protocol such as Ethernet/IP, Modbus (RTU and TCP), Profibus and others, allowing it to collect information from an already installed PLC (Figure 1).

Figure 1: A dual-role controller collects information from an existing PLC and makes it accessible remotely and securely.

A built-in web server enables users to visualize the data using a browser on an ordinary device such as a mobile or desktop PC. The dashboard can be customized using a PC-based creator tool that allows components such as switches, lamps and meters to be selected and arranged by drag and drop, and set up quickly and easily by selecting properties (Figure 2). The FP7 also supports email alerts that can be used to send status updates, event notifications, or exceptional conditions that require immediate attention.

By directing data from the existing controller to a device such as a smartphone or PC equipped with a browser (Figure 3), the FP7 provides an easy-to-use and low-cost entry point for manufacturers to explore the power of the IoT to enable smart manufacturing practices. It can be added without major disruption, and can connect to multiple automation controllers such as PLCs or other Ethernet compatible equipment, and display data from up to 16 controllers simultaneously. It can also connect to several PCs at the same time.

Collected data can be stored securely and managed on the device, and flexible sharing of the controller’s code and data registers maximizes utilization of the available storage and so saves purchasing additional expensive memory. On the other hand, it is also possible to transfer collected data to other media, such as a PC, or via Secure Sockets Layer (SSL) compatible secure communication with an FTP client or a web server on an external LAN. This allows data such as inspection data from a production line to be accumulated on the server and inspected at any time. The FP7 can also read data back from the external devices.

Companies using this approach to IoT connectivity and browser-based process management can extend their smart manufacturing by using the FP7 to transfer captured data to a Cloud-based analytical application.

As a modular PLC that can be configured with a variety of digital and analogue I/O, the FP7 also allows new sensors to be added to the system to provide more detailed information about the process or equipment being monitored. Other modules include positioning units, high-speed counters, pulse output units and remote I/O. This enables a scalable approach to smart manufacturing, permitting users to experience the power of the IoT at a minimal risk before moving on to develop a customized long term strategy.

Conclusion

The advantages of smart manufacturing can be clearly understood when looking at improved manufacturing productivity and overall business performance. However, implementing smart manufacturing in a cost-effective manner and developing scalable strategies are difficult challenges that can be complicated further by legacy equipment technical limitations. Studies, such as the IIC’s connectivity testbed, have acknowledged the need to add smart manufacturing capabilities to existing facilities with minimal changes to legacy equipment. Utilizing a dual-role PLC, such as the Panasonic FP7, offers a practical solution for realizing greater value from the data currently unavailable from unconnected automation equipment.