Jannatec Technologies takes wearables underground

Stephen Law

Electronics Optoelectronics Power Supply / Management Wireless Wearable Technology mining mining tech wearable wearableSmart Helmet is the latest wearable innovation to aid the mining industry

For more than 25-years Jannatec Technologies has lead the way as a communication solution provider of total wireless networks to the mining industry across Canada,  as well as around the world. Of late, the Sudbury ON-based designer has expanded its capabilities as a recognized innovator in wearable technology for underground communication and safety technologies.

as well as around the world. Of late, the Sudbury ON-based designer has expanded its capabilities as a recognized innovator in wearable technology for underground communication and safety technologies.

Currently enjoying 85% marketshare within Northern Ontario’s mining industry, Jannatec produces a number of rugged wearable devices, aimed at providing miners with a safer and more secure underground. Some of these items includes a vest to be worn by miners which regulates the wearer’s temperatures and monitors any spikes in body heat.

Jannatec anticipates continued success with its soon to be released ENSO Platform Helmet – which boasts lots of technology, including a 360° high visibility feature utilizing programmable LEDs, onboard brim mounted camera, bio-sensors, RFID and proximity detection.

EP&T took the opportunity to pose a few questions to Wayne Ablitt, president of Jannatec Technologies.

Q. Describe how the ENSO Platform represents the next logical step in an increasing world of connectedness for the mining industry?

For many years, communication in the mining industry has relied on LMR (Land Mobile Radio). It’s only been recently that there has been a move towards Wi-Fi and LTE, as many companies look to roll out underground wireless connectivity. The move allows for further connectivity, cost efficiency, and operational safety within the mines. Private LTE and Wi-Fi are currently being used in surface mining, and now underground is the next step. Our helmet is designed to not only work with this technological movement, but to make it easier. Not only does our product replace the typical radio communications system with more advanced voice communication delivered over Wi-Fi and LTE networks, the platform packages all the features that you currently would have in your cellular phone. Having all of these features in one allows companies to only have to purchase one product instead of many, and then only having to deal with one company.

Q. Can you describe the type of research collaboration required between Jannatec and other advanced technology and academic research partners?

Jannatec’s JETLab is a state-of-the-art facility that works in conjunction with Jannatec Technologies. It houses our incredible product designers who continuously develop the latest innovative technological advances.

In the process of the development of the ENSO Platform, our JETLab worked with a variety of government agencies and academic facilities who have assisted in the production of the helmet. One of these includes humanscope, a product development company that provides integrated research, industrial design, product design engineering, development, packaging and manufacturing services. They also have extensive background knowledge in sport/industry design in head protection PPE. Some others include head/neck load testing done by Laurentian University, and other collaborations with CEMI, IRAP, SRED, and NOHFC.

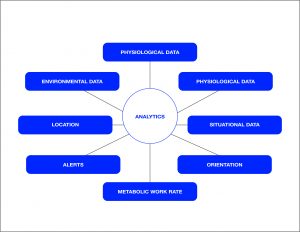

Q. Jannatec has developed a collaborative platform that will allow the industrial worker to have multiple technologies available to them. Describe those technologies.

The ENSO platform provides workers with a number of different customizable features that’s adaptable to technology that they already have. Some of these features include:

- High-Viz LEDS – 360 degrees of LEDs installed on brim of helmet for visibility

- RFID Tagging – Identify and track tags on each helmet

- Voice/ Data Communications – Connect and communicate with others

- Speakers/ Microphone – Speak with other while wearing the helmet

- Wi-Fi /Bluetooth/ LTE – Connect to Wi-Fi, Bluetooth, and LTE

- Camera – Take videos & pictures. Send in near-real time or store

- Proximity Warning – Alert workers, and drivers of vehicles approaching.

Q. Which element to the ENSO Platform was the most difficult to handle during Phase 1 of design process and why?

The most difficult element encountered during the Phase 1 ENSO Platform design was maintaining the balance between cost, performance and aesthetics. As with anytime that you ask a customer to change the way they use or look at a piece of equipment that they use daily, acceptance is vital. The key to acceptance is ensuring the following:

- Performance of the existing features isn’t affected by the change

- Performance of the new features is solid

- The equipment is comfortable and looks good.

- The value added by the new features must justify the additional cost.

If any one of the above criteria is not met, acceptance will not be met at some level in the customers company (management, safety, financial or end user).

Q. Which design element would you consider to be the most critical to delivering safety to the end-user?

Health and safety hazards in underground mining are different from those in other industries. Hazards can expand further the deeper the mine goes down, such as many mines do in Ontario. Thus, dependent on a number of factors each customer is unique, and so their needs are all different, and therefore the critical safety element may vary from customer to customer. With our ENSO Platform designed to be tailored to each individual customer, this enables them to choose which feature in the helmet they want most dominant above all other features. Perhaps that’s high-viz, or perhaps that’s voice communications. That’s entirely up the customer.

Q. What has been responsible for driving the demand for smart mining technologies?

The concept of Big Data (the growth of and digitization of global information-storage capacity) in the mining industry has been sought after now for the past number of years. The demand for a system that not only functions flawlessly, but also drives better communication between people, and people and vehicles is a constant need in this industry. Individuals are accustomed to this type of technology in their everyday life, so why can’t they have it in the mines? Our ENSO Platform will allow for this to begin to take place.

Q. Describe the importance of the successful integration of smart mining technologies in order to gain sustainable return on investments for your customers?

With the ENSO Platform technology our helmet has a variety of capabilities, one specifically being the elimination of cell paper transactions for maintenance and service checks. Looking at the mining industry and examining the many tools, and devices that are needed to complete a given task, our helmet has taken what once required a number of different devices and put it into one product. This saves companies a lot of money and elevates them from having to work with multiple companies and trying to integrate numerous products onto one network.

Q. Describe the role emerging technologies such as IoT (sensors) will have on the future development of products for Jannatec.

The Internet of Things (IoT) described simplistically is the concept that everyone is connected and everyone is connected to everything. The ENSO Platform allows for this to take place underground. It allows for connectivity not only between people, but also between individuals and their environment. An example of this would be a vehicle that has a fault in one of its sensors would send this signal to the workers and to the surface.

Q. Given the level of connectedness that exists in most business sectors today, briefly describe how far things could evolve in the mining industry.

Due to the harsh environments in the mining industry, communication and connectivity has lagged behind in comparison to most business sectors today. Currently many mines use LMR (land mobile radio) for methods of communication. However, recently a number of mines in northern Ontario are testing new LTE networks, which opens the gates to Big Data in the underground mining industry. Due to the mining down turn that occurred four years ago, mines have been slow to implement these new technologies. However, as the mining industry returns to a new state, these new systems are finally being implemented and getting up to date with the rest of the world’s current level of connectedness.

——————————-

In Addendum:

The hard rock mining industry in the Sudbury basin can be a harsh environment. For example, the ambient temperatures of the mine can be as high as 30 degrees Celsius and have an excess of 60% humidity. In this environment, the worker must follow work-rest regiments as stated by the American Conference of Governmental Industrial Hygienists.

Over the years, more attention has been paid to worker safety. Not just from the perspective of hazards in the workplace, but also from the short and long term physical effects of working in an environment where conditions can be extreme. There are mines in the Quebec region that go as deep as 9320ft. As miners go deeper underground to provide materials for which the world depends on, they need reliable equipment that is designed to handle the demanding conditions. As these mines continually expand, they will require their communication systems follow their advancements and provide high speed data to move materials to the surface.