Is it time to reshore your contract manufacturing services?

By Charles Tonna, executive VP & Mark Wood, CEO of Microart Services Inc.

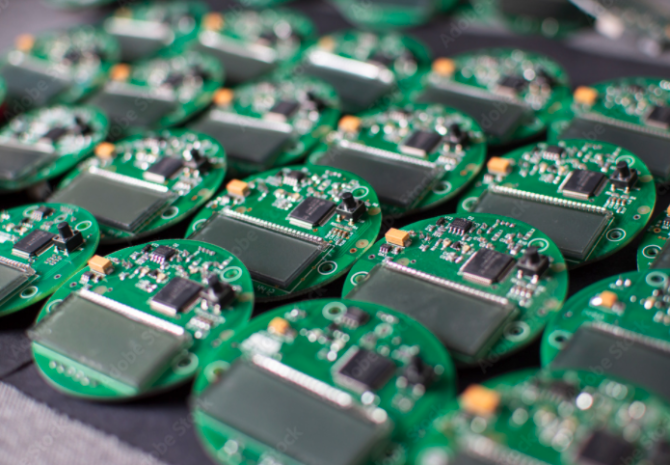

Electronics Contract Manufacturing Engineering CEM contract manufacturing electronic EMS Manufacturing servicesMicroart executives warn not to confuse price with cost when choosing a CEM partner

Now, more than ever, the world is talking about reshoring manufacturing and reshoring jobs. In the US manufacturing has become a cornerstone of policy and is seen as a key to economic recovery and the development of sustainable jobs. Many commentators are sceptical, asking if consumers will pay higher prices for their products or if brands are happy to pay more for their manufacturing, but perhaps this becomes a moot point when you really look at cost and not just at price. Let me explain what we mean.

The price of a product, or a part, is what you pay the manufacturer or supplier for that product, but that is different to the cost. Included in the cost are a number of elements that can completely change the financial outcome and if properly considered can completely change the decision making process, particularly when considering manufacturing locally or in a distant geography.

The simplest way to understand the TCOO, or Total Cost Of Ownership, is to explore the procurement process from start to finish, looking at each step along the way.

Source: Microart

- Phase One – Vendor Selection and Qualification

Selecting a vendor can be a long process and not inexpensive. Typically when looking for a new vendor or manufacturing partner a brand will start with a larger list which is eventually whittled down to a shortlist. From this point the potential vendors will need to be reviewed, audited and tested for quality and performance.

The cost of doing this in a distant geography is massively higher than it would be locally. Often a team of several manufacturing, product and quality engineers will be deployed onsite to audit a manufacturer’s processes and equipment. Taking a group of four or five engineers from Europe or the US to Asia for a week to undertake such a process might cost in the region of US$30,000. It might be possible to undertake more than one audit in that time, but the chances are you will have to visit multiple locations on multiple occasions.

Next up is the bidding process, which in itself can be extraordinarily time consuming. For offshore manufacturing the bidding process is more challenging for a number of reasons. Firstly, you’ll be up nights doing conference calls with a different time zone explaining and sharing your requirements. Secondly, you might be dealing with complex contracts that make it hard to compare apples with apples. And thirdly you’ll have to manage things like overseas payment and currency and tax variations. That’s before we even get into the uncertainty of trade tariffs.

Source: Adobe Images

- Phase Two – Design, Prototyping and NPI (New Product Introduction)

We’ve built numerous prototypes and launched hundreds of new products for our customers and it is rarely as straightforward as you’d hope. A close connection between design and manufacturing is essential to make that process go smoothly. In some ways proximity to design can trump even proximity to the end user. During the prototyping process it is essential to work through as many iterations as needed to get the product right for the market and to ensure that DFM (Design for Manufacturing) has been optimised. Good DFM results in a smooth transition from prototype to NPI, to bridge production and through to volume production. Any failures at this point will be very costly down the track.

We work closely with our customers at this point, often having them on the line as they make engineering changes and we advise on tweaks that will improve manufacturability and yield and even reduce the cost of manufacturing as we simplify assembly or test processes.

Undertaking this work remotely is extremely risky and can easily result in additional costs and more commonly in delays. Delays are expensive and we’ll cover those later. Again, language and culture can play a part in getting this process right the first time, but perhaps more importantly being able to make repeated and rapid product tweaks at this early stage will likely result in a better product and a better manufacturing process that is more robust and reliable.

- Phase Three – Ongoing Vendor Management

A well-known supply chain consultant once told me that “you don’t get what you order, you get what you measure”. That advice stuck with me and I know anecdotally that constantly measuring the quality of output from vendors is the only way to ensure you continue to get what you need. This means sending quality engineers to the factory when you need them there, often at short notice. It might even mean having someone permanently deployed at the vendor’s site, especially in the early stages of a vendor relationship or a product life. This is not an inexpensive undertaking, even if you have the boots on the ground to do it.

Your quality approvals and certifications will likely require that you regularly audit your vendors and perhaps even audit their tier one and tier two vendors as you go down the supply chain. Never underestimate the cost of this audit process when working with distant geographies.

We all like to think that we can make things right every time, but hardware is hard and we should not forget that. Manufacturers will make mistakes, they will have challenges and they will have supply chain disruptions. If we learnt nothing else in 2020, we surely learnt that life is unpredictable. When things go wrong you and your manufacturers need to be joined at the hip working together to get things right. Solving problems is when the rubber really hits the road in most vendor partnerships and this is the last place you want to incur extra costs or resistance.

Source: Microart

- Phase Four – Logistics and Fulfilment

So landed cost might not seem like a big deal, after all shipping a container around the world isn’t so expensive in the 21st century, the world’s a small place. Well, not exactly, this year the cost of sea freight has risen and capacity has dropped. Ports have come under stress with anti-pandemic precautions contributing to long and unpredictable delays. As for airfreight, we’ve lost a lot of belly cargo space, that’s the freight capacity on passenger flights, impacted by the pandemic.

It is also important to remember that there are phases of the product life cycle where sea freight is simply not quick enough or agile enough. Sea freight demands that you have several weeks of inventory on the ocean, which in itself has a cost to finance, but it also means that small product changes take a long time to find their way to the end user and sudden changes in demand are hard to meet. Often brands find themselves having interim shipments flown in to meet the demand of the market. Worse still demand might be lower than hoped and some of the product passing through the Suez canal might end up as redundant stock. The world is moving faster than ever and product design and fulfilment need to keep pace, often sea freight just doesn’t cut it in terms of getting stock on the shelves when and where it is needed.

- Phase Five – Product Development

We’d all love to believe that when we send a product to our manufacturer that product is perfect and the design will be settled for the foreseeable future, but this is rarely the case. For that reason we need an agile manufacturing process that can give us the flexibility to develop on-the-fly. We don’t want to build the airplane while we’re flying it, but we do want to be able to make tweaks without delaying launch and without bringing production to a standstill when changes are made.

Again these changes often require some production line effort to ensure they do not have a negative impact on quality or lead times, and of course cost. The challenge and cost of doing this from afar are considerably greater than if the manufacturer is local. And there’s the stock in transit mentioned previously to consider, they won’t see the engineering change and may be rendered useless as a result.

Source: Microart

- Phase Six – Risk Mitigation and Management

2020 has taught us that we need to balance just-in-time with just-in-case. Inventory was seen as a costly enemy, but too little inventory puts your supply chain at risk of disruption. The result is that risk management and mitigation are more important than ever as we plan future supply chains and manufacturing strategies. Proximity drives visibility and visibility itself reduces risk. Shorter supply chains also mean that everything in the supply chain is readily available and not tied up in customs or in transit.

Resilience and agility were seen by many as contradictions, but they are in fact two sides of the same coin. An agile, short, flexible supply chain is like a tree in high winds, it will bend and flex to weather the storm rather than break.

Risk management is all about partnership and working very closely with a manufacturing partner to have a risk management and mitigation policy will provide the insurance and assurance you need to sleep at night.

The Soft Costs – delays in getting to market, peace of mind, trade tariff uncertainty…

Manufacturing overseas has many costs that are hard to quantify in dollars. Challenges with an NPI might result in not getting the right product to the right consumers at the right time. Missing a market window can be disastrous for a product launch and for the brand delivering that product. If first-to-market advantage is important timing may be everything.

The Microart team, led by CEO Mark Wood.

Can you put a price on peace of mind? I don’t think so. You may be measured on the prices you achieve but you can be sure the c-suite and the sales and marketing team will hear all about it if the supply chain is disrupted and you miss a product launch deadline or if your supply chain stalls through some disruption. Peace of mind also comes from some level of certainty of cost. If you’re buying somewhere that might be subject to trade wars or tariffs then you are at the whims of others, perhaps politicians and that doesn’t make for a relaxing experience. You may save a few cents per part buying aggressively overseas, but those few cents may cost many dollars when something doesn’t go exactly according to plan.

Don’t underestimate the stress the team will be under from all of the travel and the late night conference calls with your overseas vendors. They may not complain, but their performance may be hampered by the pressure they are under. NPI can be stressful at the best of times, this year may have been the worst of times for NPI, but building a close bond with a local supplier can certainly help reduce that stress a little.

If you’re Apple and you’re outsourcing billions of dollars in smartphone manufacturing, then a few million dollars here and there for vendor management might not impact you product cost, but for most brands these costs add up very quickly and often don’t find their way back to the purchaser who simple sees the lower price and assumes he is doing his job well. It is essential that supply chain managers and purchasers fully load the cost of doing business with a vendor to fully understand the TCOO of any specific part or product.

As a supply chain manager, a product manager or a buyer you’re often measured on the cost savings achieved and that might be based on the price, not the cost.

————————-

Microart Services Inc. is an electronic manufacturing and design services company providing printed circuit board layout. The firm is located in Markham Ontario.