How to Decide On a Custom Enclosure Style For Your Electronics

By Protocase

Electronics Production / Materials Supply Chain custom custom electronics Electronics enclosures enclosures Protocase ProtocaseAt Protocase, we offer a variety of different enclosure styles that are completely custom-made to fit the needs of each individual customer. With that many options available, it can sometimes be overwhelming sifting through all of the possibilities, especially if you are unfamiliar with sheet-metal design.

In order to determine your best option, we recommend asking yourself a few questions:

- Where will my enclosure need to be stored?

- What electronics and components will be housed within the enclosure?

- Where will these electronics and components need to be placed?

- How durable do I need this enclosure to be?

Once you’ve answered those questions, this enclosure style guide should be able to point you in the right direction.

Sometimes called a “clamshell,” a U-Shape enclosure design is highly versatile, and can solve a number of issues even in its most standard form. You can easily tell determine that it’s a U-shape because each of the two parts of the enclosure forms a U-like shape.

For many enclosures, the U-Shape is the simplest to design and manufacture. It’s an excellent option to use when you have a component that protrudes from adjacent (meaning neighbouring) sides, such as a circuit board.

Unlike the U-Shape enclosure, in which its two parts resemble the letter “U,” one of the two pieces in an L-Shape resembles, as you might guess, the letter “L.”

While similar to the common U-Style enclosure, Protocase’s two-piece L-Shaped enclosures have distinct differences which make them ideal for PCB enclosure designs with connectors protruding from multiple/opposite sides.

An L-Shaped enclosure’s open area on one side of its bottom piece (the L-shaped piece) will allows PCBs with protruding connectors to slide right into the side of the enclosure.

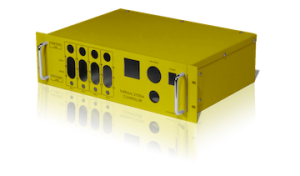

A rackmount enclosure is designed to be mounted in a racked cabinet, thanks to its side rails that allow for easy insertion and removal from the cabinet. This style of enclosure is commonly used for small and large servers.

Rackmount enclosures are measured and classified by “U,” which refers to the height of the enclosure’s front panel. Each “U” equals 1.75” (44.45 mm), with rackmount enclosures going as high as 12U.

Rackmount enclosures typically are designed to be a standard 19” wide, however, because Protocase specializes in custom, we can do a fully custom design in whatever dimensions you require.

The distinguishing factor of Protocase’s extruded enclosures is their extruded sides, which can be used for mounting PCB boards inside the enclosure. Because of this, extruded aluminum enclosures are considered an aesthetically pleasing, sturdy and low-cost option for housing components for small and large equipment.

Much like an L-Shape, an extruded enclosure helps with the issues that arise when there are connectors protruding from multiple or opposite sides. However, keep in mind that no connectors can be placed on any of the extruded sides, as the extrusions cannot have any cutouts.

With its easily removed top (or cover), the five-sided enclosure is one of our most versatile templates. For one, the top/cover can be converted to a door/lid by adding a hinge and a latch. As well, you can use a five-sided enclosure as a portable cabinet, or a wall-mounted enclosure, depending on your needs.

Protocase can build fully custom computer enclosures, big or small. These designs often start off as standard rackmount, U-Shape, L-Shape, ATX, or mini-ITX enclosures. However, unlike an off-the-shelf enclosure that you need to customize manually after you’ve purchased it, we have the ability to add all of the brackets, connectors, and other components that you require within the case to secure all the parts in place.

Using 3-axis and 5-axis vertical CNC milling, Protocase is able to mill machined enclosures from solid bar stock. This allows us to create an incredibly durable enclosure with a high level of protection from the elements, and can be highly effective while completely immersed in water.

A hybrid enclosure has the combined traits of an extruded enclosure and a machined enclosure. They have a sheet metal top and bottom, custom machined back plates, and extruded sides. If you require a design that’s solid and durable, that can easily allow for mounting a PCB, a hybrid enclosure is your best option.

Due to the extruded sides, a hybrid enclosure cannot be sealed as well as a machined enclosure, which means it is not as effective at protecting the interior against the elements. If you require an enclosure that is effective at protecting against harsh weather, dust, dirt, and water, a machined enclosure would be the ideal choice.

Often used in the audio-visual industry, a consolet can be easily distinguished by its angled front, which is often used for mounting the enclosure upon flat surfaces such as desktops or pedestals. This type of enclosure is ideal for mounting small control or instrumentation devices where the desired access requires a 30- or 60- degree surface.

Often, customers will have the bottom of these enclosures fitted with rubber feet so that they can be moved around more easily without causing scratches or scrapes to the surface, or damaging the bottom of the enclosure.

If none of the enclosure styles listed above appear to meet your design needs, it is likely that you will require a fully custom enclosure. Luckily, Protocase can manufacture a fully custom enclosure to your exact specifications by either sending us your CAD drawing outlining your design, or working with our expert design services.

A lot of factors come into play when designing custom enclosures. The rest of the enclosure styles are all standardized designs that do not have much variance. However, when you allow things like welding, hinges, cam locks, or electronic components to enter into a design, there is always a tolerance issue that needs to be addressed. If you’d like to go the route of a completely custom enclosure, please contact us early in the process so we can assist you.

Conclusion

With so many varied enclosure styles to pick from, the choices can sometimes be daunting. This guide should be able to help you select the style that best suits your needs. Remember, during your decision-making process, it’s a good idea to first consider how you’ll be using the enclosure, where it will be stored, and what electronics and components will be deployed within the enclosure.

Ultimately, we are here to make your design vision a reality in 2-3 days, in a custom enclosure that best suits your needs. If you’re still unsure about which route is best for your design, don’t hesitate to contact us by emailing info@protocase.com. Happy designing!