Cleaning printed circuit boards at the benchtop

By Emily Peck, senior chemist at MicroCare, LLC

Electronics Production / Materials cleaning pcb pcba productionVarious options dissected for application within electronic production environment

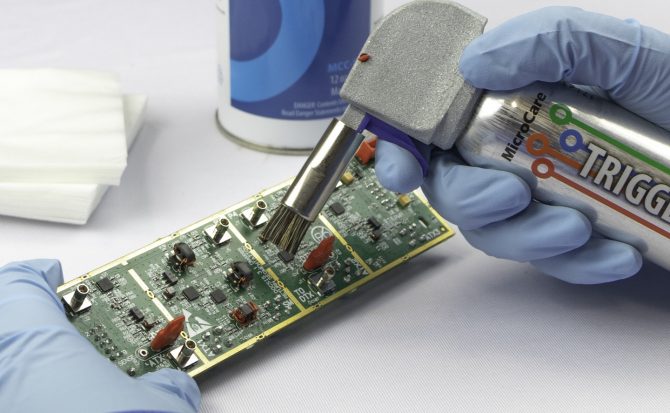

A controlled dispensing system improves bench-top cleaning results, reduces cleaning fluid waste and enhances worker safety.

Benchtop or manual cleaning is an important step in the assembly of printed circuit boards (pcbs). Whether it be during initial manufacture, for touch-up during post-reflow assembly or for rework and repair, it is critical that you properly clean pcbs before moving on to the next step in the manufacturing process. Before shipping brand-new or repaired circuit boards out the door, manufacturers must remove all contaminants including adhesives, fluxes, fingerprints or other materials.

Anything left on the board that isn’t meant to be there may negatively affect the performance of the board. This is why so many companies consider pcb cleaning a mission-critical process. If the cleaning is not effective, the finished product simply will not function reliably for the required life of the product. Better cleaning directly translates to more reliable pcbs, which means better finished consumer and industrial electronics in the market.

There are three primary methods and tools used to clean circuit boards at the bench top: Dip and brush, aerosol sprays and dispensing tools.

Dip and brush method

The dip and brush technique typically uses an acid brush and a pump bottle of IPA (Isopropyl Alcohol). Most pcb cleaning experts do not recommend this type of cleaning because it often results in a cross-contaminated pcb.

Dispensing directly from the can doesn’t allow any real cleaning control.

For instance, if you spot-clean flux residue from a section of a recently soldered pcb, you dip an acid brush into the cleaning fluid on the spring top of the pump bottle. Then you brush around the soldered areas. The cleaning fluid dilutes the flux on the pcb, but it only spreads the contamination without actually removing it. Often the diluted flux relocates elsewhere on the pcb including under neighboring SMT components. Some of the flux also makes its way onto the brush. As the cleaning fluid evaporates, it leaves the flux residue on both the pcb and the brush.

The brush is now a source of contamination as it drags deactivated flux back into the pump bottle. Also, the pump bottle valve gradually clogs with flux residue and fails to re-seal. This allows the dirty cleaning fluid on the top of the pump bottle to slip back into the bottle itself. All this adds contamination to the next board when using the cleaning fluid and brush again.

If you must use the dip and brush method, it is best to clean and rinse the whole board with clean fluid. Also, be sure to replace the dirty fluid in the pump bottles frequently. Clean the pump bottles, including the bottle valves, prior to refilling them. Also, replace the brushes often to avoid cross-contamination.

Dip and brush cleaning offers little in the way of process control. Some technicians apply more pressure in cleaning than others. Some use too much fluid, and some barely wet the board. Improvised cleaning typically results in inconsistent cleaning results.

As circuit boards become more densely packed and tighter spaced, it is increasingly difficult to use the dip and brush method and still meet pcb cleanliness standards. Quality cleaning requires pure, fresh solvent, which cannot be easily achieved with a pump bottle and IPA.

Drying the board with a lint-free wipe helps remove contaminates under low-standoff components.

Aerosol sprays

Aerosol cleaning solves many of the problems related to the dip and brush method. Aerosol sprays prevent the introduction of new contaminants by providing a steady stream of uncontaminated fluid throughout the cleaning process.

However, dispensing directly from the can doesn’t allow any real cleaning control. A fan of fluid sprays out over a wide area, resulting in a messy and expensive waste of cleaning fluid. Plus, spraying directly from an aerosol can exposes technicians to excess cleaning fluid fumes which makes for an unpleasant work environment.

Adding a straw attachment allows for more control and delivers the fluid with pin-point accuracy under low-mounted or tight-fitting components. This reduces waste and fumes, but any cleaning power relies solely on the pressure of the fluid to blast out trapped contaminants. Similar to the dip and brush method, aerosol sprays do not have any real process controls and results vary widely depending on operator use.

Wet, scrub, rinse and dry

Successful pcb cleaning requires four steps. Wet, scrub, rinse and dry. First, wet the board with a pure cleaning fluid to loosen the contaminant. Second, scrub the circuit board with a brush to remove hard-to-remove particulates or oils. Third, rinse away the contaminants with more cleaning fluid. Finally allow the board to air-dry or dry the board with a lint-free wipe.

The dip and brush method allows you to wet and scrub, but makes it impossible to rinse the contamination from the board, so the board looks poorly manufactured and often remains sticky with fluxes even after cleaning.

The aerosol spray method also allows wetting, but doesn’t provide any scrubbing power. A solution is to outfit the aerosol spray can with an attached brush. The cleaning fluid flows through the brush head and allows for good scrubbing of dirty areas.

One of the most important steps for successful pcb cleaning is the rinse. Quality rinsing is essential to quality cleaning. If you can’t rinse, you can’t clean. It is important to ensure that all flux residue washes off the board, otherwise you’ll redistribute it back onto the board.

Most pcb cleaning experts don’t recommend the ‘dip & brush’ cleaning method.

Controlled dispensing system

When used properly, a controlled dispensing system improves benchtop cleaning results, reduces cleaning fluid waste and enhances worker safety. With a dispenser hose attached to an aerosol can of cleaning fluid, the technician has better control of how much and where the cleaning fluid is dispensed. They spray cleaning fluid exactly where they need it without overspray, reducing wasted fluid.

The dispensing system typically includes options for brush and syringe attachments. They help get under low surface mounted components for more thorough cleaning. The cleaning power of the fluid is augmented by the scrubbing action of the brush. Contamination loosens and rinses away with little effort and minimal cleaner. Technicians typically use up to 60% less cleaning fluid when they use a controlled dispensing system.

Plus, using a dispensing tool reduces landfill waste. The system uses every drop of fluid inside the aerosol can. It is more environmentally friendly to dispose cans that are not partially filled with residual fluid. In addition, a dispensing system enhances worker safety. Since the dispensing tools are closed systems, technicians do not pour fluids from pails or drums. This reduces the risk of spills and fire hazards. It also limits worker exposure to fumes.

Using a controlled dispensing system also offers consistent cleaning. The entire cleaning process can be standardized and documented to meet ISO or other quality requirements. For benchtop cleaning effectiveness and safety, a cleaning fluid dispensing system is a simple, yet effective way to help protect workers and deliver consistently clean and reliable circuit boards. It cleans more boards with less cleaning fluid which produces cost savings, quality improvements and environmental benefits.

Prepare for cleaning success

Modern pcb cleaning is a mission-critical process. If not done correctly the pcb will not function reliably for the required life of the product, resulting in field failures. To clean pcbs effectively and reliably at the benchtop, it is important to use the four-step cleaning process of wet, scrub, rinse and dry. Also consider using an appropriate cleaning fluid and a controlled dispensing system to produce consistently clean pcbs.

——————————

Emily Peck is a senior chemist at MicroCare, LLC, which offers benchtop and vapor degreasing electronics cleaning solutions. She holds a MS in Chemistry from Tufts University.