Calgary CEM August Electronics expands its footprint

By Sohail Kamal, West Coast Correspondent

Electronics Contract Manufacturing contract contract Electronics electronics manufacturing ManufacturingCo-founder Peter Wilson shares his insights on the firm’s move into an 85,000-sq-ft facility

The founders of August Electronics, a contract electronics manufacturer (CEM) based in Calgary AB, recognized a problem: They were growing out of two busy facilities that limited its ability to manage operations efficiently. The oil and gas boom produced strong sales, but it also led to a tight real estate market. The CEM recognized that one large, unifying space would help them reduce cost, upgrade equipment and expand capacity. Then the oil bust occurred, and the opportunity arose to seek out opportunity in the rubble. West Tech Report recently spoke with one of August Electronics’ founders, Peter Wilson, to expound on the firm’s recent move to a new world class facility and how it has helped them prepare for the future.

Q: Great to see an Alberta CEM poised for growth – what was the impetus for the move to an 85,000 sq. Ft. space?

Previously, we were operating two facilities which was not very efficient, but the abundance of real estate during the downturn presented us with the exciting opportunity of building a new facility from scratch. We applied what we had learned over the previous 25-years to create an efficient layout and workflow that allows us to continue growing – when the eventual economic rebound takes place. So far it appears to be working out well. Since moving to our new facility, sales are up 60%.

Q: How has the oil and gas downturn affected the industry, and how are you preparing for the future?

Alberta’s economy is still reeling and it’s possible that the glory days of the oil and gas industry are over, which has undoubtedly affected any CEM’s with oil and gas customers. One of the benefits of a downturn in the oil and gas industry is that a lot of tech-savvy individuals are now involved in start-ups that span many industries.

Our future growth will depend on generating awareness of the benefits of having electronics built locally. Often, start-ups think they have to go overseas for cost-effective manufacturing, which is really not the case. Internally, we are continually scrutinizing and improving our processes, upgrading our equipment, and expanding our capacity to serve a diversified client base.

Q: How do you differentiate from your competition?

Mainly, we are more accommodating. We’re a one-stop shop, offering everything from consigned circuit board assembly, to full-turnkey with lots of mechanical assembly and direct shipping to end users. August Electronics focuses on being a strategic partner that consults with customers to understand their products, applications, and business rationale.

Q: Tell us about the new space and how does it set August Electronics apart from others?

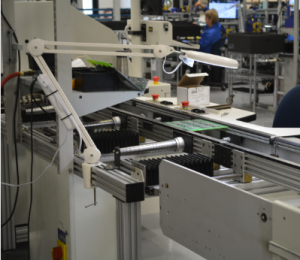

We’re proud of having excellent shop floor control and smooth workflow. We have a lot of space, and that allows us to handle the diverse requirements of our customers, keep everything tidy and organized, and still have room to grow. We can afford to dedicate space to special processes, such as repair of abused oil-field instrumentation and calibration of hazardous-gas detection equipment.

Q: Moving can be risky. What sort of challenges did you face?

We had 25-years of production experience to rely on, so we knew pretty much what we wanted. The main challenge was to get it built properly and on-time. Our best advice is to have a clear vision, a great contractor, and visit the site every day.

Q: How about some advise for the budding entrepreneur?

It’s pretty simple: Hire great people, take the long view, don’t cheat, and own your mistakes.