Aito brings surfaces to life with sensing, haptics technology

Stephen Law

Electronics Engineering Editor Pick haptics Sensing SensorNetherlands-based developers of patented and award-winning piezo sensing and haptics technology, Aito is on a mission to deliver a heightened user experience by bringing surfaces to life in the field of tactile feedback.

En route to having more than 80 patents, the firm has built a significant portfolio of intellectual property in electronic sensing, control, signal processing and mechanical construction. This has enabled Aito to deliver a fully integrated haptic solution, allowing electronic designers to create intuitive touch experiences housed in elegant designs.

Aito’s patented finger sensing and haptic feedback solution includes what the firm calls “the world’s thinnest haptic touchpad.” Here, EP&T speaks with Aito CEO, Nedko Ivanov, who has more than 27-years of international experience in the high-tech sector gained within blue-chip multinationals and venture capital backed businesses.

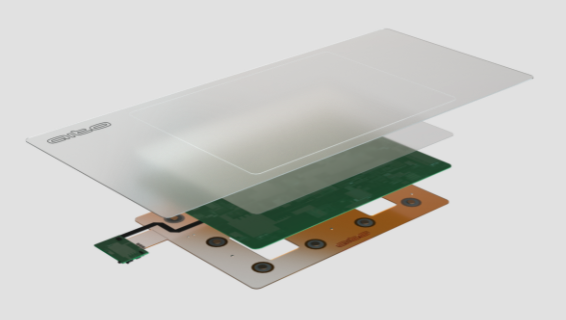

Haptic Stack includes: overlay; capacitive touch pcba, and an ultra-thin haptic sensor that integrates multiple standard off-the-shelf piezo discs carrier. Source: Aito

Q. Describe the technology behind the integrated finger sensing and haptic feedback touchpad.

We have built our haptic touch technology into a multi-layered haptic stack. This consists of an overlay, a capacitive touch printed circuit board assembly (pcba) and an ultra-thin haptic sensor with an electronics module containing our proprietary mixed signal haptic IC and Aito Controller hosting our firmware with Aito algorithms. The sensor has multiple piezo disks that sense the precise location of where a finger makes contact with a surface. These disks then give an instantaneous pulse of feedback simulating the sensation of clicking on a mechanical touchpad.

Our haptic technology can detect both the pressure and manner of how a surface is touched and provide different, localised feedback based on this. The number of piezo transducers in a device can be scaled up to the required level enabling coverage of a wide area and extremely precise and high-fidelity haptic feedback. This is customisable by strength, sensitivity and sharpness – altering how powerful the feedback feels and how much pressure is needed to identify a push for a click.

Surface sensations such as ‘multi-level press’, ‘spring effect’ and ‘scroll haptic’ can also indicate different actions on a surface, such as activating caps lock on a haptic keyboard and providing haptic sensation when your scroll up and down a page using the haptics touchpad.

Q. What sets the Aito surface touch technology apart from existing haptic feedback platforms already in the marketplace?

Our haptic solutions are thinner, more precise, and more versatile than those currently on the market. Our touchpads measure 2.4mm thin compared to 4mm for most other touchpads. The Piezo disks allow our technology to sense exactly where on the surface a finger has made contact and only give feedback in that precise location. Other haptic solutions – such as those behind an Apple MacBook touchpad– will send feedback across the whole surface as opposed to directly where the finger makes contact.

Our solutions also allow the haptic area to be any shape and size – the surface can be much bigger for users that require large areas, like graphic designers, or smaller for users that may need a compact solution. No matter the size, our haptic touchpads and keyboards come under a single surface without gaps and grooves for a truly seamless design.

Last but not least is it very power efficient using ultra-low power in standby mode with instant wake-up which is paramount for battery powered devices.

Q. What applications is the technology being designed into now?

Our focus is currently on laptops – we have integrated our haptic technology into touchpads with our haptic keyboards in progress. However, our technology can scope much further: it is compatible with touch screens, laptop accessories such as mouses, and even AR/VR accessories, though these are not a focus for us just yet.

Q. What are the most common design sectors implementing the technology? (i.e. industrial, automation, medical, IoT, etc.)

The great thing about haptic technology is that its applications are virtually endless. Although our core function is consumer electronic devices, finger sensing and haptic touch technology can be developed for many different applications in other market segments.

It is predicted that the haptics market is experiencing a compound annual growth rate (CAGR) of more than 13% to 2026. In the near future I expect we will start to see it implemented into technology everywhere.

Highly integrated haptic electronics module. Source: Aito

Q. What are some of the design benefits to engineers creating new electronic devices?

The main advantage of creating devices with haptic technology is that designers can create more versatile devices that are significantly different to competitors – a task that is particularly challenging for designers of current consumer devices such as laptops.

Current laptops on the market typically combine a screen with two mechanical elements: a touchpad and a keyboard. Although they function perfectly well, the devices lack features that truly differentiate them from others on the market. This in turn leaves price as the most significant differentiator, driving margins lower.

This is where haptic technology comes in – to give designers a competitive edge. Our touchpads are more versatile and customizable. Our haptic touchpads are also significantly thinner than other haptic touchpads, creating more room for larger batteries or allowing for slimmer and less obtrusive devices.

Another benefit of haptic touch relates to manufacturing. A complex issue that laptop manufacturers face stems from keyboards. There are in the region of 40 different keyboard variants used around the world reflecting different languages and layouts. Separate keys need to be created and assembled into devices to make them language specific. This means that for every global laptop created, there will be upwards of 40 different models, based on the keyboard alone, adding huge complexity to the supply chain. It also complicates the issue of shifting stock being between high selling and low selling locations – a laptop with a Korean keyboard will be of no use to an English-speaking consumer, without significant alteration.

Haptic touch combined with a display can offer consumer device manufacturers a universal keyboard that can be programmed to change languages without requiring any changes to the underlying device’s hardware – much like a mobile phone can be set up in different languages. This would allow for the international shipment of stock and create a more efficient supply process.

Building a keyboard using a seamless plain of material instead of fitting 100 or so keys requires less materials. It also eliminates the problems with consumers losing or breaking keys and reduces the risk of liquid ingress – building devices with a solid, impenetrable surface will reduce the rate of keyboard-related device returns and replacements. This ultimately saves companies money and reduces e-waste.

Aito CEO, Nedko Ivanov

Q. How customizable is the technology for designer purposes?

As previously mentioned, our technology allows the strength, sensitivity and sharpness to be altered by users depending on their preferences. This has huge benefits for the user experience and ultimately gives users more freedom to customise their devices.

Our solution is also compatible with almost every material, including wood and leather. This means devices can be designed to look and feel very different to current models on the market, and it gives the option for consumers to purchase more sustainable devices such as those that are built with recycled materials.

Q. Describe some of the patents Aito has managed to secure and the importance they play in rolling out this new haptic technology.

Aito has a strong commitment to building a powerful portfolio of intellectual property to help drive technical leadership and ultimately maximise shareholder value. We have 85 patents (52 granted and 33 pending) with the majority of these expiring beyond 2033. The patents are primarily related to three key areas for haptic touch. These are: electronics and signal processing where we have a portfolio of 20 patents granted and a similar number pending; electro-mechanical construction (20 patents granted and five pending) and the critical area of sensing and control (with seven granted and nine pending). Combined this offers one of the most comprehensive patent portfolios in haptic touch.

Q. When do you anticipate Aito will have its technology fully commercialized?

We are planning to go to market in early 2022 with a leading consumer brand – sadly I cannot say more than this. We are hoping in the next few years our haptic touch solutions will be rolled out into devices around the world.