Advanced materials may help U.S. recapture leadership role in semiconductor biz

By Adam Khan, founder of AKHAN Semiconductor

Electronics Optoelectronics Semiconductors Supply Chain advanced chips diamond materials nanocarbon optical semiconductor Sensing siliconThere has never been a better time to be truly recognized as innovators and leaders in the space

Since the ‘60s, almost all semiconductor devices have been made with silicon, showing a concerning lack of advancement for a critical technology. When you consider the leaps and bounds made in other crucial technologies, like computational power, artificial intelligence and beyond, there is a need to shift the focus to advanced materials as we look to revitalize the semiconductor industry.

For more than a year, many factors have played a part in disrupting the semiconductor supply chain and exposing its fragility, including geopolitical factors, the COVID-19 pandemic, global transportation issues and more. The extensive and endless series of unfortunate events that have wreaked havoc on the supply chain has brought microchips to the mainstage of the global economy, spurring countless mergers and acquisitions, as well as uncertainty.

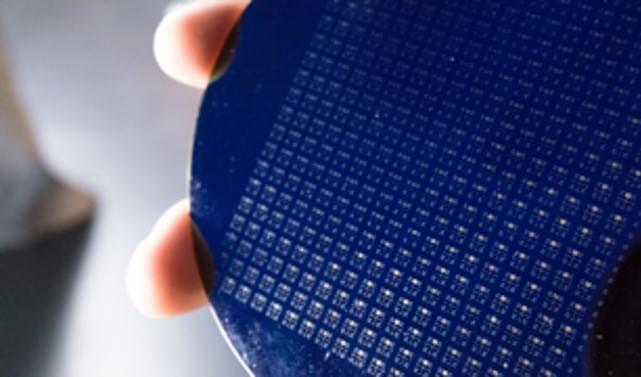

Source: Akhan Semiconductor

Given the current state of the industry, there has never been a better time for those who want to be truly recognized as innovators and leaders in the space, to reassess their global approach and improve the industry by prioritizing the development of advanced materials. There are several reasons why the world at large stands to benefit from advanced materials when compared to industry standard silicon. With silicon, there are disadvantages and limitations in capabilities preventing the development of lighter, faster, and more energy-responsible electronics.

Advanced materials, like diamond, far outmatch silicon materials in their ability to diffuse heat, handle huge amounts of power and take up far less space. Devices relying upon advanced materials are also able to run hotter (with the ability to operate at temperatures over 300 degrees to be specific) without degrading performance, ultimately reducing the cost of cooling systems and overheating repairs. In comparison to industry-standard materials, advanced options are equipped to handle voltages that are 10 times higher and operate at over 90% increased power efficiency. They are also generally more cost effective and environmentally friendly. Compared to silicon, these alternate materials are uniquely able to isolate massive voltages with a fraction of the material, taking up less space by being 1,000 times thinner than those that use silicon.

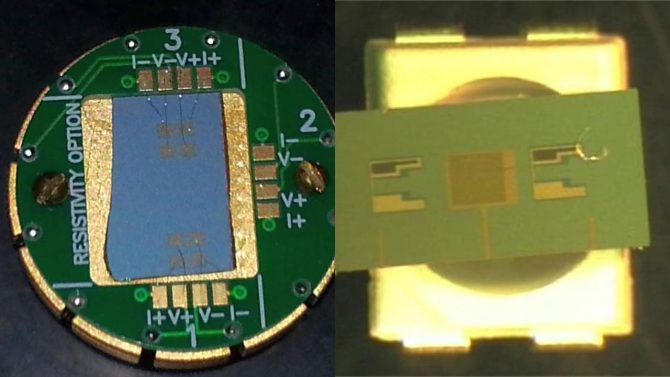

Source: Akhan Semiconductor

Multiple industries stand to dramatically improve from advanced materials including Gallium Nitride (GaN), Gallium Oxide (Ga2O3) and Indium Phosphide (InP) in terms of performance and capabilities. While there are a number of materials that can improve performance, lab grown diamond has been proven to be the most optimal semiconductor material and stands to enhance capabilities across a variety of highly important and competitive industries, including aerospace, defense, automotive, consumer electronics, telecommunications and more.

Across automotive and consumer electronic industries, we’d see lighter cars that operate more efficiently, along with devices that would be thinner, lighter and more durable. Advanced materials would also aid in improving the battery life and systems for a range of devices including cameras, phones and display screens. What makes the switch to advanced materials even more appealing is the near effortless change to processes that would need to be made. Thanks to modern breakthroughs in manufacturing and fabricating, the ability to implement these new materials without overhauling existing silicon-based semiconductor manufacturing processes is possible.

Provide benefits & solutions to temperature regulation difficulties

In aerospace and defense avionics, hypersonic flight, guidance systems and optical systems used in satellites, lasers, telescopes and targeting systems, provide benefits and solutions to the temperature regulation difficulties inherent within these systems. Heating and cooling in aerospace is a major issue where performance is negatively impacted by electronics becoming too hot. Through the usage of advanced materials, electronics can operate at higher temperatures and fly with less weight, improving flight efficiency.

Advanced materials are also pushing the development of optical components for manned and unmanned aircrafts, like multilayer anti-reflective diamond coating systems that are ultra-hard, scratch resistant, produce high thermal activity and account for chemical and biological inertness, which are all necessary qualities when addressing optical sensing, optical detecting and craft electronics. Protective coatings using advanced materials provide an effective countermeasure to state-of-the-art direct energy weapons, including electromagnetic and high-energy laser systems. Without these protective coatings, enemy weapon systems have a greater ability to take down jets and helicopters without explosives.

Using diamond as a semiconductor material in electronics has many advantages. The comprehensive Miraj Diamond® Electronics portfolio is at the center of AKHAN’s ability to manufacture next-generation diamond semiconductor technology.

Advanced material protective coatings

Aircrafts outfitted with advanced material protective coatings specifically address various optical components when it comes to manned and unmanned aircrafts:

Optical Sensing – Current materials lack the hardness, strength and thermal shock protection needed for optical sensing applications in defense, but advanced materials protect optical components against directed energy, oxidation and debris, without adding significant system weight and without significant optical loss.

Optical Detecting – Materials typically used for detecting lack sufficient strength and thermal shock resistance to meet current defense application requirements and are in need of advanced materials that can bring the hardness, strength, high optical transmissivity, and thermal performance required to enable the next generation of detector systems.

Craft Electronics – Considered the most vulnerable electromagnetic weaponry, craft electronics are responsible for performing critical functions from supporting flight to enabling reconnaissance. Unlike materials that are commonly used, advanced materials can be directly integrated with craft electronics to keep devices operating within thermal budget and without adding extra weight.

Incentivize innovation with advanced materials

Beyond everyday electronics, semiconductors are an important part of the technology that keeps us safe, making it clear that world leaders should take note of advanced materials for reasons other than commerce and innovation, and prioritize their development. For influential world leaders like the U.S., Canada, the U.K., and other allies in Europe and Asia, to incentivize innovation with advanced materials will enable the growth and advancements of crucial technologies, as well as world defense initiatives.

Now, more than ever, the world at large understands just how important semiconductor technology is. Shortages on automobiles, cell phones, gaming consoles and other technology that’s become part of our daily lives amplifies our awareness. But now, with the benefits of advanced materials understood, it’s time to move beyond silicon-based chips to increase capabilities and global progress.

————————–

Adam Khan, is the founder of AKHAN Semiconductor, a premier semiconductor company focused on diamond and nanocarbon technologies, based in Gurnee, IL.