CAMI increases wire test system production

EP&T Magazine

Electronics cable harness production wireFirm further develops automation with CableEye ready cable and harness testers

CAMI Research Inc., Acton MA, has extended its production facility by adding 2000-square-feet of new production space for manufacturing the firm’s CableEye brand wiring test systems.

Despite the pandemic, 2021 sales were the highest ever for CAMI, regarded as an essential manufacturer in the supply chain for defense and medical industries. As a result, all areas of the business remained operational through the pandemic.

CAMI Research Inc., Acton MA, has extended its production facility by adding 2000-square-feet of new production space for manufacturing the firm’s CableEye brand wiring test systems. Source: CAMI

The company has been a leader in innovating highly configurable test solutions for simple and complex multi-conductor cables and harnesses for nearly thirty years. CAMI provides these advanced wiring analyzers and guided assembly systems to discerning global customers who require accurate and dependable assembly and testing in order to deliver top quality product. Systems are used for countless test applications of products destined for transportation, aerospace, energy, appliances, medical devices, defense, robotics, telecom and much more.

Trusted by industry leaders, CAMI has shipped thousands of test systems globally over the years to such recognizable players as CERN, Ford, GE, Hitachi, NASA, Abbott, TESLA, Lockheed Martin, Raytheon, Airborn, Furukawa, TE Connectivity, and the Nobel prizewinning group, LIGO.

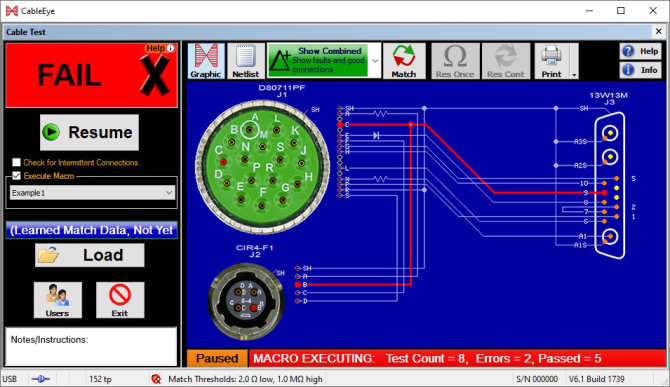

CableEye Wiring Tester Production Screen. Source: CAMI