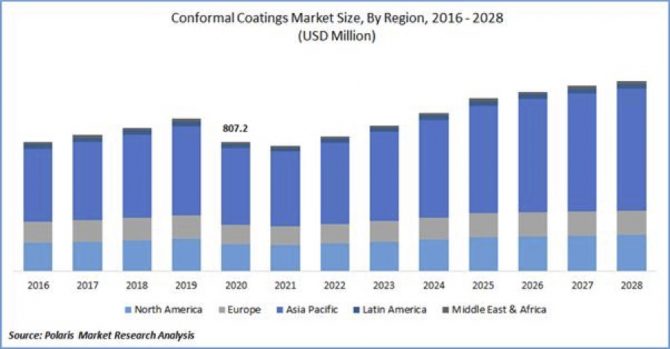

Conformal coatings market to grow to $1.18B

EP&T Magazine

Electronics Production / Materials chemical coatings conformal materials pcbPolaris report indicates the rise by year 2028

The global conformal coatings market size is expected to reach USD 1.18 billion by 2028 according to a new study by Polaris Market Research. Conformal coatings are a protective cover that could be a polymer or a chemical film that is applied on electronic circuits to give them long-lasting protection from moisture content and chemical contaminants in the air. These products maintain insulation cover, ensure continuity of circuit board components and oversee functional integrity of the circuit board.

A huge market for consumer electronics, rapid strides in medical equipment, and the emergence of driverless cars are some of the important factors driving the conformal coatings industry. Furthermore, the rise in disposable incomes and dependence on sleek electronic devices such as mobile phones, laptops, and other gadgets have fueled the growth of particular products that are mandatorily used in electronic components.

Material to protect sensitive information on PCB

Automotive is one of the most far-reaching segments for these products. The development of hybrid cars is consistently empowered by technology and witnesses a comfortably high growth rate being touted as an energy-efficient alternative. Electric cars and hybrid vehicles could give a more comfortable ride, optimum fuel efficiency, and use more electronic gadgets, giving rise to the sophistication that is the foundation of EV’s.

Initially, these products were the mainstays in medical and military products but with high cost per unit. But, with innovations and with rising of material science, prices have reduced considerably over the last few years. Recent technological nuances in the market include low viscosity solvent-free conformal coating, parylene-like hydrophobic conformal coating, and single component conformal coating material to protect sensitive information on PCBs.

PCB assemblers favour conformal coatings for economic, environmental reasons

These products are unique based on their material of formulation. These coatings are used, bringing to the fore their characteristics and required efficiency. Acrylic conformal coating is the largest product segment by material. Polyurethane, epoxy, and parylene are amongst the fast-growing segments.

Most of the product manufacturers, device fabricators, and printed circuit board (pcb) assemblers favour conformal coatings for economic and environmental reasons though solvent-based ones prop up performance. A move towards green chemicals has certain resins moving at a faster rate as compared to traditional ones such as acrylics.

The report gives a detailed insight into the current market dynamics and provides analysis on future market growth. For more info visit: https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/request-for-sample