Electronic tattoos fit wearable computing designs

By Lisa Kulick, Carnegie Mellon University

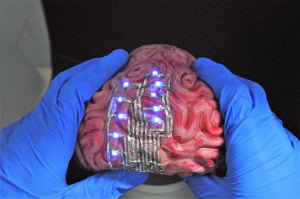

Electronics Engineering Software Regulations & Standards Engineering Supply Chain Wearable Technology circuits circuits tattoo tattoo wearable wearableThese stretchable, inexpensive, tattoo-like circuits were made with an inkjet printer at Carnegie Mellon University

Researchers from Carnegie Mellon University’s College of Engineering and the Institute of Systems and Robotics of the University of Coimbra, Portugal have developed a simple, efficient method to make robust, highly flexible, tattoo-like circuits for use in wearable computing. The low-cost process adds trace amounts of an electrically-conductive, liquid metal alloy to tattoo paper that adheres to human skin. These ultrathin tattoos can be applied easily with water, the same way one would apply a child’s decorative tattoo with a damp sponge.

The tattoos can conform and adhere to highly curved 3D surfaces, like a model of the human brain. Photo Source: Carnegie Mellon University

Other tattoo-like electronics either require complex fabrication techniques inside a cleanroom or lack the material performance required for stretchable digital circuit functionality on skin.

Carmel Majidi, an associate professor of mechanical engineering and the director of the Soft Machines Lab at Carnegie Mellon, and Mahmoud Tavakoli, the director of the Soft and Printed Microelectronics Laboratory at the University of Coimbra, teamed up to develop methods for direct printing of stretchable electronic circuits. Their collaboration succeeded.

“This is a breakthrough in the printed electronics area,” said Tavakoli. “We showed for the first time that inkjet-printed patterns of silver nano particles can be sintered at room temperature using the gallium indium alloy. Removing the need for high temperature sintering makes our technique compatible with thin-film and heat sensitive substrates.”

“The technique is simple. The tattoos are ultrathin, very stretchable, and inexpensive to produce.” — Carmel Majidi, Associate Professor, Mechanical Engineering

The ultrathin tattoos can be applied and removed easily with water. Photo Source: Carnegie Mellon University’s College of Engineering

In addition to low-cost processing, these tattoos provide other advantages. Because they have mechanical properties similar to lightweight fabrics, they remain functional under bending, folding, twisting, and strains above 30% (which is the typical stretchability of human skin). They can conform and adhere to highly curved 3D surfaces, like a model of a human brain or a lemon.

Applications for ultrathin, compliant tattoos include epidermal bio-monitoring, soft robotics, flexible displays, and 3D-transferable printed electronics.

The findings were published in Advanced Materials in a paper titled “EGaIn‐Assisted Room‐Temperature Sintering of Silver Nanoparticles for Stretchable, Inkjet‐Printed, Thin‐Film Electronics.”