Will 3D printing play a role in the next manufacturing revolution?

Stephen Law

Electronics Contract Manufacturing Engineering Printable ElectronicsEP&T Magazine spoke with 3D printing expert Daniel Stolyarov, Ph. D., CEO, Graphene 3D Lab Inc., a spinout of Graphene Laboratories Inc. and creators of conductive graphene filament for 3D printing.

——————————-

Q. Many consider recent progress in 3D printing to be the start of the Third Industrial Revolution. Describe the role 3D printing is expected to play in the future development of modern manufacturing.

A. Every Industrial Revolution has introduced a new way to automate the way we make things. The first industrial revolution began when the spinning jenny, a steam-powered version of the spinning wheel, was invented. Henry Ford sparked the second industrial revolution with large scale assembly lines. Both developments introduced manufacturing automation thereby reducing the cost of goods.

3D printing is yet another step in this direction. It simplifies the manufacturing process by making the design and the actual manufacturing of the product separated by one push of a button. Design and final product are only separated by one step—the push of a button. We want to take this even further by introducing concurrent printing with multiple materials.

All functional things around us are built from a variety materials, each with different functionalities (i.e. structural, electrically conductive, semiconductor, thermally conductive, and so on). 3D printing technology, once capable of combining these materials during printing, eliminates the assembly process. This technology will require a set of functional materials suitable for this 3D printing process. The development of these materials and technology is the mission of our company.

Q. How big a role does the development and adoption of graphene play in the future success of 3D printing?

A. Developing a series of functional 3D printable materials is a challenge. Metals are commonly used as electrical conductors. Although metals can be used in some varieties of 3D printing, they can’t be co-printed with commonly used 3D printing polymers due to the tremendous difference in melting temperatures.

We are working on the development of materials that differ by functionality but are still very similar to each other from a processing perspective. Nanocomposites provide an elegant solution. By mixing a nanomaterial, such as magnetic nanoparticles with a polymer matrix, we can come up with a material that will behave like a polymer and yet attain magnetic properties.

Graphene nanoplatelets are an important nanomaterial. Graphene-based nanocomposites can be formulated as thermal or electrical conductors. Graphene nanoplatelets can also be used for mechanical reinforcement of polymers.

Q. Describe some of your firm’s product successes including the 3D Printed Graphene Battery, as well as Conductive Graphene Filament. What are the advantages and applications?

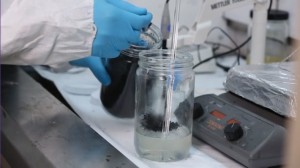

A. Our conductive FDM filament is an example a functional 3D printing material created by mixing graphene platelets with polymer matrix. The graphene platelets form a conductive network which provides the conductivity for the resulting composite.

We exploited the same principle when making a fully 3D printable battery. In this case we used polymer with high ionic conductivity as a matrix and a conductive graphene network acts like an electrode. We also added some compounds that participate in an electrochemical reaction and produce electricity.

Q. Though still in the early stage of commercial development, 3D printing has many possibilities to improve the design process? Describe what the future of 3D printing looks like.

A. First of all, 3D printing is the ultimate prototyping tool. It makes the turnaround time extremely short, thus allowing the designer to make multiple iterations in the gadget design. Eventually, 3D printing will be capable not only in creating the prototypes but the actual products. At that point people will be able to manufacture goods at home. It will also become possible to download and exchange gadget design files to be manufactured easily at home in the same manner people exchange computer software and smartphone apps nowadays.

We made a first step in this direction when we launched ShareStation3D – a web portal when people can exchange their designs for 3D printed products. Unlike similar web sites, ShareStation3D has a focus on sophisticated engineered projects where 3D printing is used for making functional objects involving electronic circuitry.

Q. Does 3D printing technology have the capability to challenge the traditional mass-manufacturing model?

A. In my opinion, although 3D printing will occupy a substantial share in overall manufacturing it will not completely eliminate the conventional manufacturing technology. Primarily, this is because conventional manufacturing is quite mature and it might take a while before 3D printed products will be able to compete with goods produced by conventional means in quality and performance. Secondly, 3D printing is an inherently expensive process of making goods and there always be the need to produce bulk identical items at a low price. 3D printing shines when there is a need to produce a single unique item. There’s a similar situation with printers. Everyone has a laser printer or similar in their house. Yet, it’s much cheaper per unit to print these pages using offset printing as you would with published books or magazines. There will always be a need to produce single items on demand.

Q. Is it possible for new companies to develop innovative business models built on 3D printing?

A. Without any doubts! The economy of scale has its dark side: although price goes down with the number of identical items being made, the opposite is also true: the price of making a single unique item is high. 3D printing is capable of reducing this burden and becomes a handy tool when a new product is introduced. 3D printing will simplify the developing process by making design iterations faster and less expensive and also can be used for making actual products before production volume is high enough to warrant conventional manufacturing. 3D printing can also be employed for manufacturing discontinued and obsolete parts.

Q. Describe how innovations in 3D printing will allow for the creation of a variety of products, such as printed electronic circuits, sensors, or batteries to be manufactured.

A. Our Holy Grail is to make it possible to 3D print electronic components. The conductive filament can also be used for making resistors. We have already developed a method for 3D printing batteries. We will need a specialized software tool that would allow combining the mechanical design with electronic design and arranging the electronic components in the design 3D printed device.

The 3D printing provides a very exciting capability of incorporating distributed network of sensors inside of 3D printed objects. The sensors could be compression sensors or temperature sensors or any other type of sensors that could be 3D printed. When this technology will be applied for manufacturing robots, the robots will be getting closer to having humanlike abilities and senses.

Q. Describe how some of your firm’s newer technologies have the potential to bring 3D printing to the next stage of commercial development.

A. The mission of our company is to revolutionize the 3D printing technology and make it capable of making working devices. We are planning to accomplish it by introducing a line of functional materials formulated for 3D printing.

We recently developed and start offering a conductive graphene based filament for desktop FDM printers, which are very popular nowadays. The filament can be ordered from our web site BlackMagic3D.com. The volume resistivity of this filament is ~1 Ohm*cm which allows you to use this filament for 3D printing conductive traces.

Some models of FDM printers equipped with multiple printing heads allow for combining several materials in one print. In particular, one can combine our conductive filament with regular plastic used for FDM printing. This opens the possibility of making Printed Circuit Boards on a home 3D printer.

To make this technology available to electronic designers, we developed several software tools that are capable of converting standard PCB design files (Gerber) files into the design files for a 3D printer. Development of these tools was done in collaboration with Jeff Casey, owner of Rockfield Technologies. By using these tools, one can use his or her home 3D printer for making a multilayer pcb board rather than have it manufactured in a PCB house. We shared these tools on the ShareStation3D web site and on the web site of Rockfield Research. There is also instructional video on YouTube. We encourage electronic designers to use these tools to make their projects easier.

We are working on developing other exciting products–a filament with improved thermal conductivity that will be useful in making heat sinks and a magnetic filament, to mention few.

Q. Describe which business (design) sectors you anticipate being big adopters of 3D printing technologies. Some already include aerospace, automotive and defense.

A. I believe that 3D printing should not be an exclusive toy for big industries such as aerospace and automotive. As I already mentioned, the 3D printing is the ultimate prototyping tool and will be extremely beneficial to small startup companies in the course development of innovative products. I envision that with our products and the software tools we developed, 3D printing will become an instrument in every electronic shop.

——————————————————————————

Graphene 3D Lab Inc. provides two versions of the pcb to STL conversion tools developed independently. One of the tools can be downloaded from the firm’s ShareStation3D web site, as well as links to instructional videos:

http://sharestation3d.com/circuit-converter

The other tool was developed by Graphene 3D Lab Inc. collaborator Jeff Casey, a founder of Rockfield Research Inc.

http://www.rockfieldresearch.com/pcb2stl/index.html

Here is the link on the video tutorial:

https://www.youtube.com/watch?v=0Bemq3b_Bqw