Multi-cure conformal coating steps-up protection, improves pcb performance & security

Stephen Law

Production / Materials Contract Manufacturing Supply Chain conformal coating conformal coatingFor many years manufacturers of electronics (OEMs) have been looking for a coating that allows them to hide information on their circuitry and provide environmental protection. With the release of its newest conformal coating option, Electronic Coating Technologies, Brampton ON, figures it has found the solution.

In the past this task has been done primarily using epoxies as potting compounds or glob top materials. This requires several steps in the before the application of the epoxy. Silicone molds, dam and fill gasket application or placement of the circuitry in plastic potting cases.

Multi-Cure 29816, a ‘true’ black UV curable material – comprised of a single-component, 100% solids, light and heat curable conformal coating- is designed to enhance security on printed circuit boards (pcbs). In addition to its ability to improve circuit reliability in harsh conditions, its opaque black color is intended to cover markings, labeling, as well as sensitive information on the circuit board.

Another use is as a conformal coating on LED circuit boards used in the manufacture of LED displays and lighting fixtures. The matt black finish improves the optics of the LEDs by creating a surface that does not reflect unwanted light.

Lighting display companies that wanted a black background to their displays have needed to use two component epoxies or polyurethanes to get the desired display effect. This process has been time consuming and inefficient from both a waste and time standpoint. The use of one component fast curing materials dramatically streamlines the production process.

Formulated with a secondary heat cure, 29816 can typically be applied and cured at up to 5 mils thick – in one pass. It’s easily dispensed and for thicker coating requirements the material can be applied in multiple passes. It becomes immediately tack free after curing, helping to avoid handling defects such as fingerprints that may be left on the boards if they are handled too soon, or other damage caused by stacking and arranging the printing boards during processing. Moreover, this multi-cure material can be applied to a variety of substrates including glass reinforced epoxy laminates, and various substrates found on components on PCBA’s with a good bond. In essence, the 29816 coating has been developed to cover sensitive information as with all chemistries testing need to be done to determine adhesion to specific substrates for maximum security. Electronic Coating Technologies provides automated atmospheric Plasma treating capabilities to enhance adhesion to circuit assemblies when maximum adhesion is required.

The 29816 is applied like other conformal coatings by PVA Selective Conformal Machine. The use of the automated application allows application of the black conformal coating material around LEDs without the need for masking LEDS or keep out areas on a PCBA. The use of UV Curable black conformal coating and automated application equipment greatly reduces material and associated applications costs compared to traditional potting processes.

Typical processing consists of application of the coating to the PCBA with a PVA robot and then transferred to either an inline PVA curing tunnel or a Dymax stand alone curing tunnel. This process lends itself to safe environmentally friendly application of materials. While typical 2 component potting compounds lead to the creation of waste, both environmental and in manufacturing time, solvent free single component coatings and encapsulants allow for lean manufacturing techniques and reduced hazardous wastes.

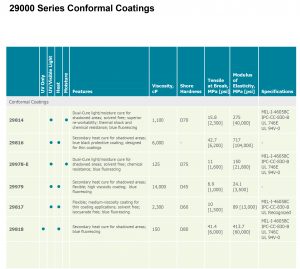

29816 is yet another addition to the TEC Conformal Coatings product line, which includes UV/heat-curable as well as UV/moisture-curable materials in a range of viscosities, all providing circuit board protection and shadow-curing capabilities. Their ability to cure in seconds enables faster processing, greater output and lower processing costs. When cured with Dymax light-curing spot lamps, focused-beam lamps, or flood lamps, they deliver ideal speed and performance. Dymax lamps offer the ideal balance of UV and visible light for the fastest, deepest cures

Light-curable conformal coatings help ensure pcb reliability in environments where moisture, condensation, dust, dirt, salts, chemicals, abrasion, thermal shock, mechanical shock, and other factors can all affect circuit performance. Each of our conformal coatings is one part (no mixing required) for easy dispensing and is electrically insulated so it can be applied over the entire pcb surface or in select areas to provide protection from service environments.

These conformal coatings are solvent-free and contain very low VOCs, eliminating the need for solvent handling. Many are formulated with secondary cure mechanisms (heat or moisture) allowing for curing in shadowed areas. Fluorescing grades are also available, making it easier to see coating placement and coverage. IPC approved, MIL-I-46058C and UL listed grades are also available.

These conformal coatings are solvent-free and contain very low VOCs, eliminating the need for solvent handling. Many are formulated with secondary cure mechanisms (heat or moisture) allowing for curing in shadowed areas. Fluorescing grades are also available, making it easier to see coating placement and coverage. IPC approved, MIL-I-46058C and UL listed grades are also available.

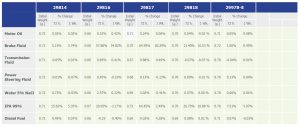

Chemical resistance testing:

Six conformal coatings were tested for their chemical resistance against a variety of fluids commonly found in the automotive industry. Conformal coatings were applied to pcb and cured for 20 seconds with a Dymax 5000-EC flood lamp (200mW/cm2). The pcb were immersed in the fluid for 72 hours, after which they were removed and wiped clean. They were then left at room temperature for one week. The chart below shows the initial weights of the boards, the weight of the boards after one week, and the percentage of weight change.